Cowan Dynamics

This article has been reviewed by Cowan Dynamics Application Engineering team. Contact Us and our application engineers will assist you with your application.

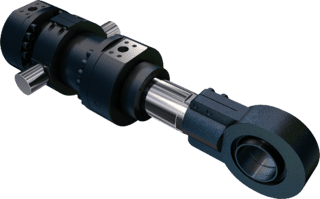

Mill-Type cylinders are cylinders designed to fill a need for a more durable, more reliable product to reduce down-time and maintenance costs. Based on design specifications that are not subject to NFPA limitations, the mill-type cylinder has heavy-duty construction with steel flanged end caps, heavy-wall steel tubing, bigger pistons, bearings, advanced gland design, and numerous other features. The mill-type cylinder also has a high pressure rating which is well above industry standards. Together these features assure greater reliability under the severest environmental and operational conditions.

The main difference between between a mill-type cylinder and a NFPA cylinder is that the mill-type is not constrained to NFPA limitations and as a result, the rod bearings are extra long. Some of the major design features of a mill-type are:

- 5000 PSI pressure rating

- Extra long piston rod bearing provides longer bearing life than conventional NFPA rod bushings

- Dual wiper design, consisting of a Polyurethane wiper and metallic scraper; keeps contamination out of the cylinder for maximum seal life.

- Custom mountings designed to suit specific application.