Valves are used to control the flow of fluids in process control applications by opening, closing, or partially obstructing the fluid flow and controlling the line pressure. Depending on the flow requirements of the industrial process system, some method of changing the positions of valves is needed. Some valves are operated with hand wheels or levers. Other valves must be open, closed, or throttled frequently. Manually positioning valves in these types of situations is not practical and instead of using hand wheels or levers to control actuation, automated valve solutions such as using a valve actuator for positioning the valves.

What is a valve actuator?

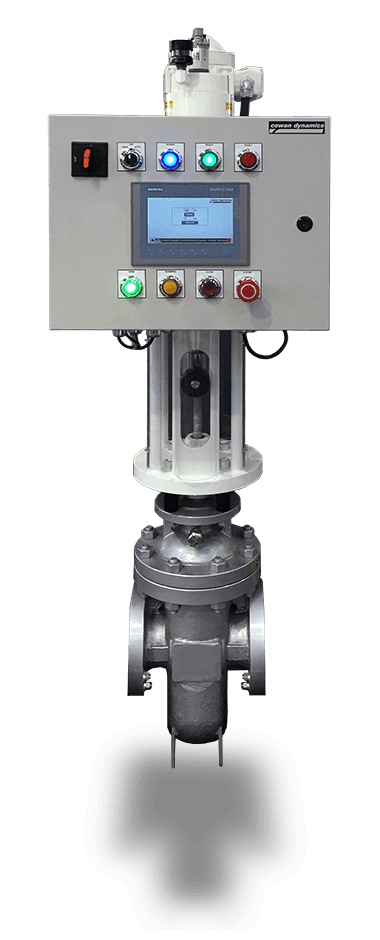

A valve actuator is defined as a mechanical device that moves or controls a device such as a control valve. Actuators reduce the need for operators to go to every valve that needs repositioning and operate the valve by hand.

When valve actuators are used for valve control, the actuator can be operated from a remote location such as the control room. Valve actuators can easily operate the valves accurately and quickly.

Control valve actuators are used with valves that are designed for throttling or regulating flow. Valves that are used to automatically throttle flow are generally referred to as control valves.

Control Valve Automation

Control valves can be either linear, that is, the stem moves the valve disk up and down. An example of a linear valve is a globe valve.

Or they can be rotary (1/4 turn) which means that their position changes with rotation. An example is a ball valve which provides an open or close position.

In remote API Midstream Pipeline Distribution Networks often an ESD Valve is used for emergency shutdown purposes. An ESD Valve actuator will be installed on the valve for this purpose.

Examples of different types of valves:

Types of Actuators

There are 4 basic types of valve actuators: pneumatic actuators, hydraulic actuators, electro-hydraulic, and electric actuators.

Pneumatic Valve Actuator

Pneumatic valve actuators use air pressure to produce motion to position a valve and they are the most common type of actuator used in process systems.

Pros

- Lowest cost

- Most cost-effective actuator from a purchase point of view

- Fast-acting, high speed

- 100% duty cycle

- Simple to repair

- Long-lasting

- Simple to operate

Cons

- Large & heavy – difficult to install in tight spaces

- Requires expensive pneumatic air supply system that must be maintained

- Not as accurate due to the compressibility of air

Hydraulic Actuator

Hydraulic Actuators that are powered by a pressurized liquid such as hydraulic fluid are called hydraulic actuators. Compared to pneumatic actuators, hydraulic actuators of the same size are usually more powerful.

Pros

- Fast-acting, high speed

- 100% duty cycle

- Simple to repair

- Long-lasting

- Simple to operate

- Highly accurate with the appropriate hydraulic system

Cons

- Requires expensive hydraulic supply system that must be maintained

Electric Actuators (MOV)

Electric actuators (Motor Operated Valve) use electricity to produce motion.

Pros

- Simple installation

- Data logging options available

Cons

- Slow

- Limited duty cycle (typically less than 30%)

- Not available for fail-safe applications

- Difficult to repair

- Fragile

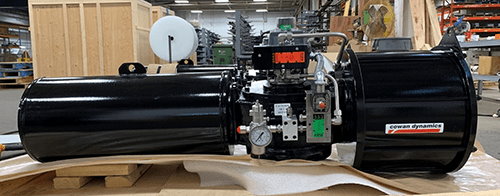

Electro-Hydraulic Actuator

Electro-hydraulic actuators (EHA) replace the need for separate, bulky hydraulic systems. They are self-contained actuators and are operated with electrical power. The electro-hydraulic actuator combines the best of both worlds of electric actuators and hydraulic actuators.

Pros

- Simple Installation – complex hydraulic supply system not required

- 100% Duty Cycle

- Fail-safe capability

- Remote Diagnostics/Data logging

- Fast-acting, high speed

- Highly accurate

- Variable speed motor allows for custom open & closing times

- Custom open & closing times can easily be set in the field

Cons

- Most expensive option

- Difficult to repair

Valve Actuator Standards, Testing & Course

Various ISA Standard & ISO Standards for valve actuators include:

- Sizing, Selecting, and Applying Process Control Valve

- Valve Actuator Testing

- ISA96.01 -requirements for terminology for valve actuators and their accessories

- ISA96.02 – requirements for electric valve actuators for both on-off duty and modulating applications

- ISA96.03 – requirements for pneumatic valve actuators of the single- and double-acting types used for on-off applications

- ISA96.04 – requirements for hydraulic valve actuators of the single- and double-acting types used for on-off and modulating applications

- ISA96.05 – automated valve includes the following:

- Limit switches and other monitoring devices

- Air regulation and filtration system

- ISO 22153:2020 – requirements for electric valve actuators, used for on-off and control valves. It includes guidelines for classification, design, enclosure and corrosion protection, and methods for conformity assessment.

[/et_pb_text][/et_pb_column][/et_pb_row][/et_pb_section]