Cowan Dynamics

This article has been reviewed by Cowan Dynamics Application Engineering team. Contact Us and our application engineers will assist you with your application.

What are the pros and cons of a butterfly valve? What options are available when selecting a butterfly valve actuator? This short and informative article will explain it all. Butterfly valves are rotary or 90-degree valves where the closing membrane is a disc that is connected to the stem perpendicularly either symmetrically or asymmetrically. They can be manual or automated, with metal or resilient seats, bi-directional, and come in wafer, lug, and flanged connections. Butterfly valves are very versatile and can be used in both isolation and control applications. However, their control capabilities are limited.

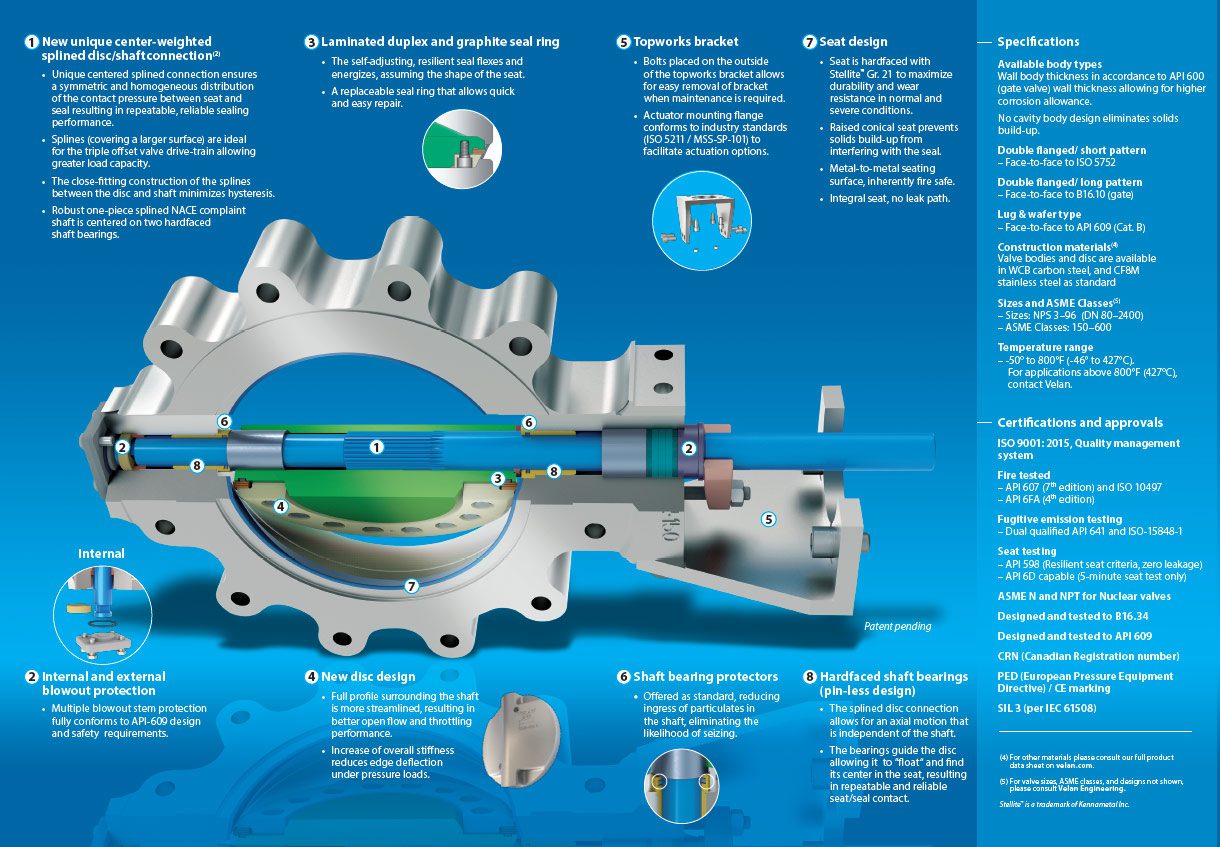

Butterfly Valve Parts Diagram Image Source from Velan

Conventional resilient seated butterfly valves are designed primarily for fluid isolation as they have poor control characteristics. The seat is an elastic single piece that holds in place the valve body. This design can have its integrity compromised if the valve is kept partially open. For this reason, butterfly valves that are designed for control or modulating operation have either a completely metal seat or a resilient seat that is mechanically retained in the valve body. When properly machined, they work well as control valves, offering a tight shutoff.

The metal seat or a resilient seat design generally requires a more robust construction due to the higher fluid velocities – which could damage a conventional resilient seat butterfly valve. A butterfly valve can be used for a wide range of applications within the water supply, wastewater treatment, fire protection, and gas supply. In the chemical and petroleum industries, butterfly valves are used in fuel handling systems, power generation and many other applications.

Butterfly Valve Actuators

Butterfly valves, like any other type of valve, require an energy source to be operated. The energy required depends mainly on the design and the pressure differential across the valve. Butterfly valve actuators can be selected depending on the source of power (hydraulic, pneumatic, electric, etc.) to the actuator. Learn the pros and cons of selecting a valve actuator in your process system for flow management.

When pneumatic pressure is available, butterfly valve actuators can be:

Double and single acting rack and pinion pneumatic actuators, Cowan Series CRP

Double and single acting Scotch yoke pneumatic actuators, Cowan Series CSY

When hydraulic pressure is available, butterfly valve actuators can be:

Double and single acting Scotch yoke hydraulic actuators, Cowan Series CSY

When electric power is available:

Double and single acting electrohydraulic actuators for isolation, Conventional resilient seated butterfly valves (ON/OFF). Cowan Series E2H90

Double and single acting electrohydraulic actuators for control, double and triple offset butterfly valves (Control/modulation). Cowan Series E2HR

When using the process gas pressure,

Double and single acting gas over oil actuators, Cowan Series CGO

Valve Standards

Below are a few engineering butterfly valve standards are:

- MSS SP-67-2017 Standard for Butterfly Valves

- PIP PNSMV007 – Carbon Steel Butterfly Valve Descriptions

- This Practice provides requirements for suppliers providing carbon steel butterfly valves included in PIP Piping Line Class Material Specifications.

- PIP PNSMV027 – Stainless Steel Butterfly Valve Descriptions

- AWWA C519 – High-Performance Waterworks Butterfly Valves-3 In. (75 mm) Through 60 In. (1,500 mm)