Welcome to Cowan Dynamics

Trusted By

Pioneering Automation for over 67 Years

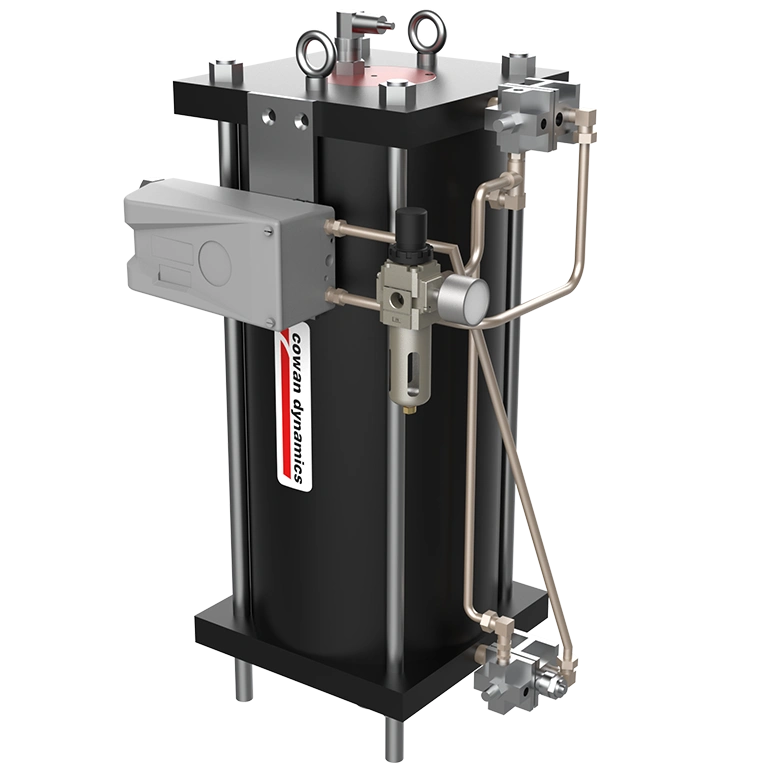

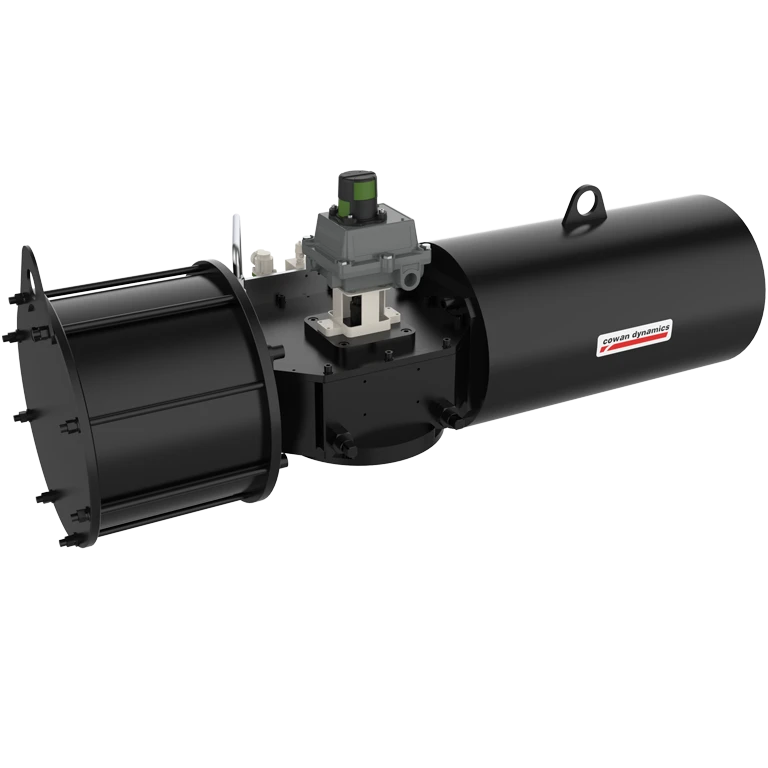

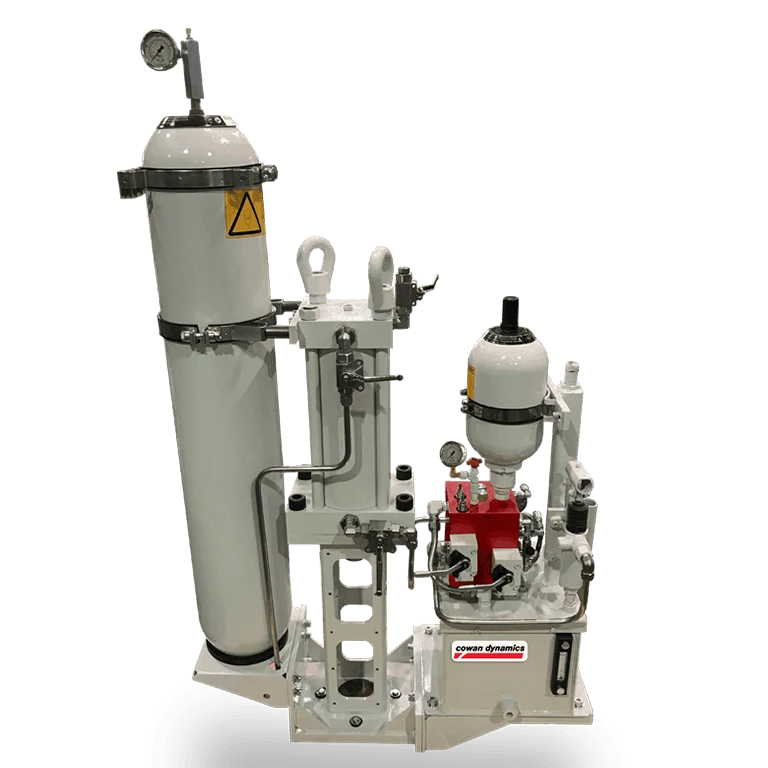

For over 67 years, Cowan Dynamics has been leading the way with our innovative valve automation solutions. Our SIL-3-capable products are used globally in harsh environments and are chosen for their safety features, product performance, and reliability.

We provide valve manufacturers and end-users with solutions focused on delivering a full array of reliable actuator products and services on time and to spec, regardless of your project’s scope, size, or complexity.

Located in Montreal, QC.

Factory size: 50,000 sq.ft

Product Launch History

Customer Testimonials

Industries we Serve

We are trusted by industries to provide state-of-the-art actuation and automation solutions for the following industries.

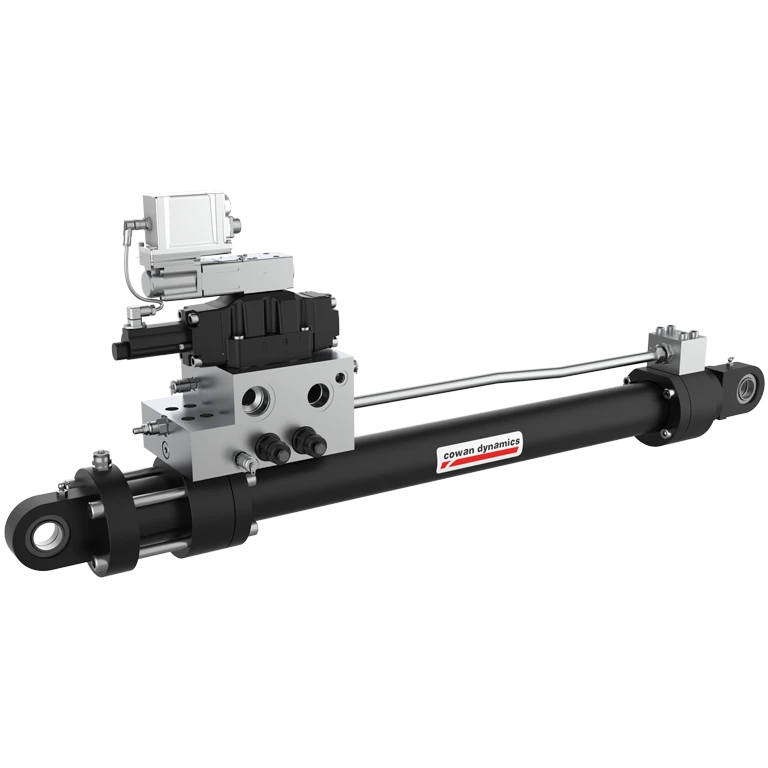

Oil and Gas

Empowering oil and gas operations with advanced valve automation, ensuring efficient flow control for upstream and downstream applications.

Chemical Processing

Maximizing chemical processing efficiency with cutting-edge automation and precision control technologies.

Mining & Processing

Boosting mineral processing productivity with innovative automation and control systems, like our dart valve automation products.

Water Treatment

Streamlining water treatment processes with advanced valve automation, such as regulating flow rates for precise flow control.

Power Generation

Enhancing power generation reliability through state-of-the-art valve automation, ensuring seamless operation of turbine control valves for optimized energy output.

Manufacturing

Revolutionizing manufacturing efficiency with precise actuation automation by optimizing the operation of advanced operations from aviation testing systems to industrial milling process control.

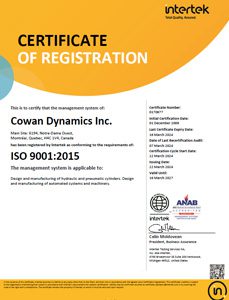

Certifications

ISO Certification: All our products have been designed, manufactured, and built in an ISO9001:2015 accredited environment.

Welding Certification: Cowan Dynamics is certified to CSA Standard W47.1 “Certification of Companies for Fusion Welding of Steel”.

Our Comprehensive Capabilities

In an industry in which no two customers’ product needs or operating parameters are exactly alike, Cowan relies on a highly collaborative approach in which all operating units work closely together, both internally and with each customer.

The result? Great solutions. Consistent product performance and reliability. Exceptional service and support. Our inside and outside sales and account management team brings extensive engineering and technical expertise to each new application.

Our sales department works with clients to identify their exact application needs. Quotations and solution proposals are prepared in liaison with our design team, which assists in pricing and developing preliminary design concepts.

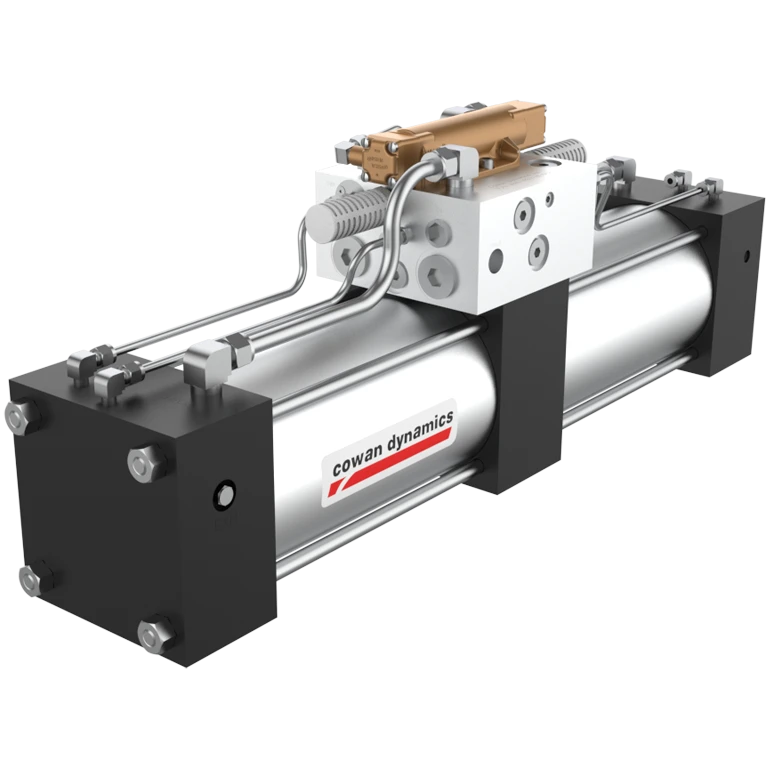

Cowan’s electrical and mechanical engineering group develops innovative design solutions that add significant automation and functionality to our actuation and process control systems. Clients have the best of both worlds: the flexibility of a highly specialized custom design shop together with full-scale manufacturing and testing facilities, all under one roof.

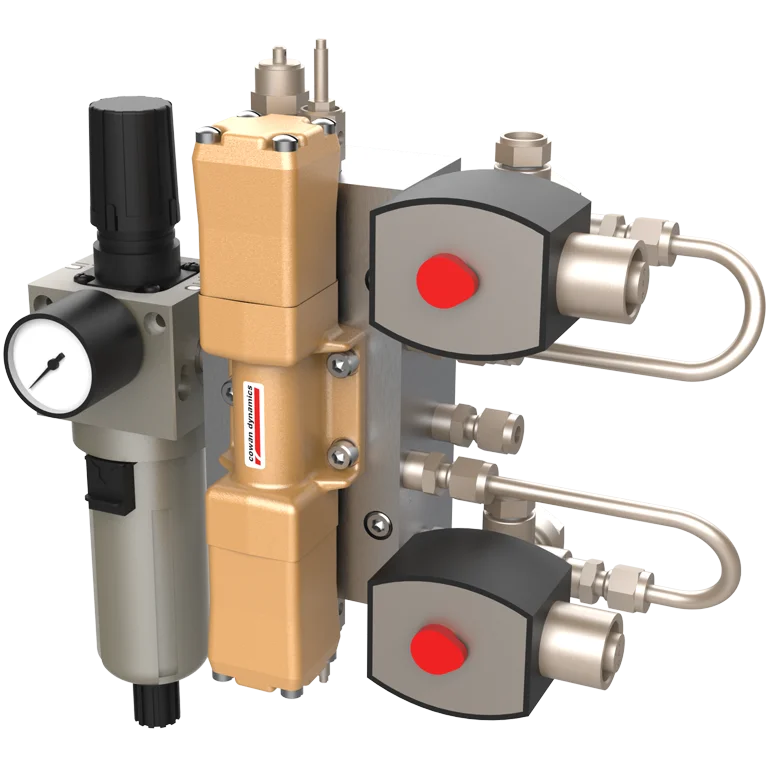

The design team uses SolidWorks 3D, Automation Studio, and other specialized design software to enable Cowan to provide fully integrated design, testing, and engineering services.

From CAD simulations to factory and site acceptance testing, Cowan’s design and production teams collaborate at every stage of the production cycle.

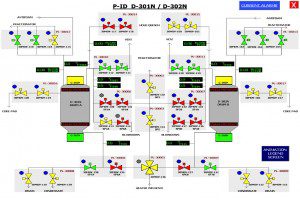

Application-specific Human Machine Interface (HMI) design puts control process data and functionality at the user’s fingertips.

To achieve maximum cost efficiency without compromising product quality and performance, Cowan’s fully integrated, manufacturing technologies and processes are designed to accommodate high-volume manufacturing as well as short-run custom components and systems.

To ensure tight coordination internally as well as with customer shipping schedules, we use automated workflow software to track and report on all components as they move through each stage of production.

From CAD-based simulations to rigorous pre- and post-production analysis and inspection, our R&D and testing resources enable us to ensure our clients that every component and system they receive will perform to specification. New products are subjected to millions of cycles of rigorous testing to ensure optimal performance in customer environments.