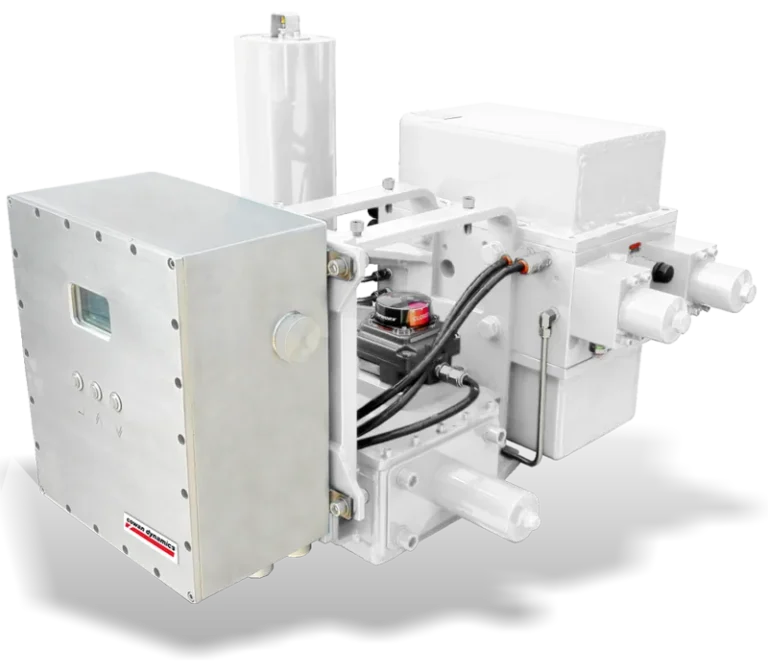

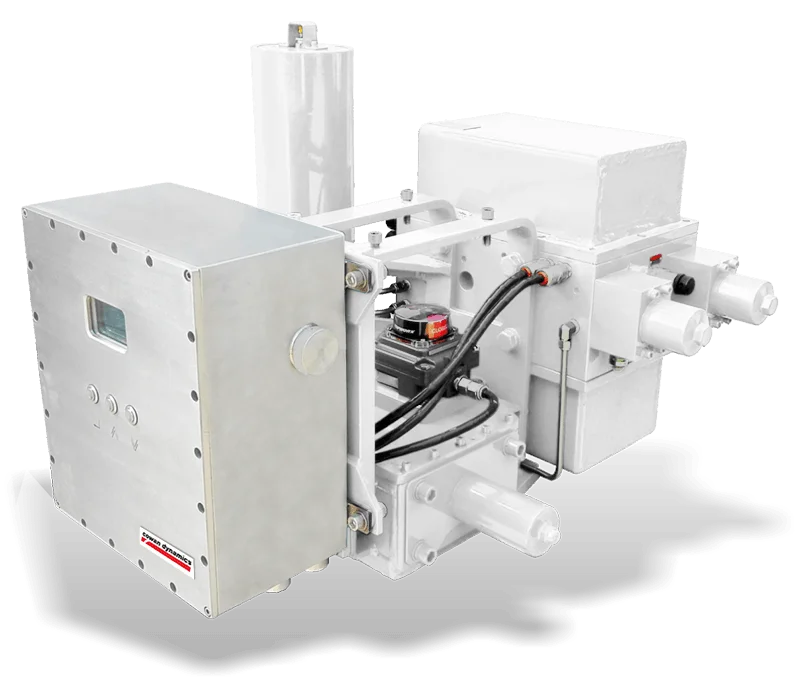

E2H90 SeriesOn/Off Rotary Actuator

The E2H90 Electro-Hydraulic Rotary Actuator is designed & engineered for ON/OFF applications.

Specifications

| Voltages | 200-240 Vac/1 Phase/3 Phase, 380-480 Vac/3 Phase, 500-690 Vac/3 Phase & Custom |

|---|---|

| Service | Isolation, on/off |

| Design | Double or single acting |

| Fail system | Hydraulic Accumulators or Springs |

| Driven by | Accumulators, sized to 2 strokes |

| Control panel | Integral or remote |

| Ambient temperature | (-40 to +70 C) |

| Protection | IP65/IP68 |

| Classification for hazardous areas | Explosion-proof rating: Ex d IIB/IIC T4 |

| Communication | Digital (standard) Feedback by HART, Profinet ,Profibus (options) |

| HMI | Local, remote and ESD function can be configured, Open and close indication, Program partial stroke test (PST) |

| Service | Duty cycle S5 (15 min continuous service) |

| Power consumption | Only when recharging accumulators |

| Movement Lock | Complete after each operation |

| Manual override | Manual hydraulic pump |

| Speed | Speed control for Open and Close |

| Mounting | Horizontal or vertical (ISO, MSS, Custom) |

| Safety Integrity level | SIL 2 (HFT)=0 ; SIL 3 (HFT>=1) |

| Ambient temperature | (-40 to +70 C) |

|---|

Design & Materials

Click on the (+) Icons to see more details.

Accumulator

Integrated Hydraulic Control System

Filter

Power and Drive Modules |

- Quarter turn stroke: -5° to 95° adjustable

- The cylinder features dual seals to guarantee zero leakage

- Symmetric and canted yokes are available to satisfy various valve torque profiles

Explosion Proof Electronic Control Panel

E2H90 Applications

The E2H90 Series has a myriad of applications.

Oil and Gas

Enhancing oil and gas processes with E2H90 Series Electro-hydraulic Actuator, ensuring precise flow regulation for optimal performance and reliability.

Chemical Processing

Optimizing chemical processing with the E2H90 Series Electro-hydraulic Actuator, enabling precise adjustment of flow for enhanced product quality and efficiency.

Mining

Improving mining and mineral processing efficiency with the E2H90 Series Electro-hydraulic Actuator, facilitating precise control over slurry flow rates for optimized extraction and resource utilization.

Power Generation

Maximizing power generation efficiency with the E2H90 Series Electro-hydraulic Actuator, enabling precise adjustment of steam flow for optimal turbine performance and energy output.

Water Treatment

Maximizing power generation efficiency with the E2H90 Series Electro-hydraulic Actuator, enabling precise adjustment of steam flow for optimal turbine performance and energy output.

Manufacturing

Boosting manufacturing productivity with E2H90 Series Electro-hydraulic Actuators, facilitating precise control over material flow for optimized production processes and quality outputs.

Datasheets & Videos

Why Use it?

Cowan E2H90 Series Self-Contained Electro-Hydraulic Rotary Valve Actuators are used for industrial process valves where highly reliable, controlled and Emergency Shut-down are required. They are used to automate rotary type valves such as: ball and butterfly valves.

For valve automation applications that require emergency shutoff valve automation, we recommend the E2H-ESD.

Independent and Adjustable Open/Close Time

The system flow rate is designed to be 20L/min. For example, the measure ESD time of a size 09 electro-hydraulic actuator is less than three seconds.

By independently setting an open/close adjustment valve in the hydraulic control system, the length of time to operate the valve by the actuator can be strictly controlled.

For example it can close or open the valve in a natural gas pipeline quickly (less than 10s) to block it, or slowly close (more than 120s) the valve to avoid the water hammer effect in a production oil pipeline.

Comparison Table

E2H-ESD

E2H90

Actuator mechanical Design

Scotch Yoke

Scotch Yoke

Failure system

Spring return, fully sealed in a compact canister. Welding’s Certified to CSA 47.1 Division 2. Option for hydraulic return on preloads higher than 306,000 lbs.-in

Hydraulic accumulators system designed to 2 strokes. Option for spring is available

Fail Function

Fail on Loss of power & ESD Signal

Fail on Loss of ESD Signal

Operational ambient temperature rating

(-50C TO 40C)

(-40C TO 70C)

Control Panel

Standard: Installed on the unit wired and tested Option: Remote

Standard: Installed on the unit wired and tested Option: Remote

Interface

Standard-Power/Overload/Open/Closed & PST light indicators. Open/Close/push buttons Option: HMI-Multi Color Touch Screen (only available with the smart PCL option)

Standard LCD Screen, circuit printed board. Navigation buttons, Open/Close buttons. Local, Remote selector

Communication

Standard: Discrete. Open/close/ESD/PST Option: Smart PCL, 4-20ma control, 4-20 ma c/w HART, PROFIBUS,PROFINET.

Standard: Discrete. Open/close/ESD/PST

Environmental Protection

NEMA 4X, IP66

IP67

Hazardous Area classification and certifications

CSA or uL or cUL CI1,Div1&2,Gr C&D OR AATEX, II 2G EEx d IIB

Ex d IIC T6

Power Supply Voltage

120VAC/60Hz/Single phase. Options available

220VAC/50Hz/Single phase. Options available

Manual Override

Standard: Manual Hydraulic pump

Standard: Manual Hydraulic pump

Partial Stroke

Comes standard, set at a set position. Standard 20% open. Speed adjustable

Comes standard, set at a set position. Standard 20% open

Fail safe time

Fast- Less than 15 secs for all models. Adjustable and padlock able

Standard : Fixed. Not adjustable. Option: Adjustable, not lockable

Stroke operation

Directly driven by the hydraulic pump. No down time, recharge not needed

Driven by the pressurized fluid in the accumulators. Accumulators sized to 2 strokes, after this accumulators must recharge

Recharge time

Not required. Unit is always available to stroke the valve

Between 15 to 30 mins depending on the model

Modular Design

Yes, Controls and hydraulics can be provided remotely mounted as a standard design if required

No

Hydraulic Design

All Hydraulic components and sensors are integrated into a compact manifold block. The complete hydraulic system is Fully enclose and pad-lockable

All hydraulic valves are included in a enclosed cabinet, interconnection between components is all done with stainless steel tubbing and fittings.

Mechanical travel stops

Mechanical travel stops +/- 5% and local position indicator

Mechanical travel stops +/- 5% and local position indicator

SIL Certification

SIL 3 (Pending)

SIL 2 (HFT)=0 ; SIL 3 (HFT>=1)

Lifting lugs

Yes

Yes