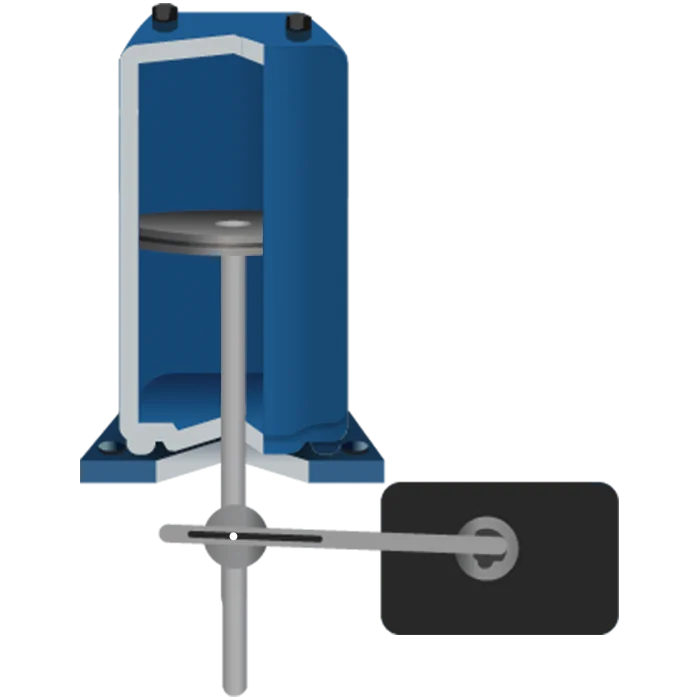

AT SeriesDart Valve Actuator

Powerful patented dart valve actuator with a self-contained transducer to replace traditional mechanical linkage arms for position feedback used in froth flotation cell systems.

Specifications

Specification Overview

| Thrusts | up to 55,000 lbs |

|---|---|

| SIL Rating | SIL-3 Capable |

| Severe Service | GT3 Triple Seal Gland for Severe Service Applications |

| Design | Compact design with self-contained transducer |

| Ease of Installation | Modular transducer for easy installation |

| Output Options | Switchable output analog or digital |

| Sealing Options | Dual- or triple-seal gland |

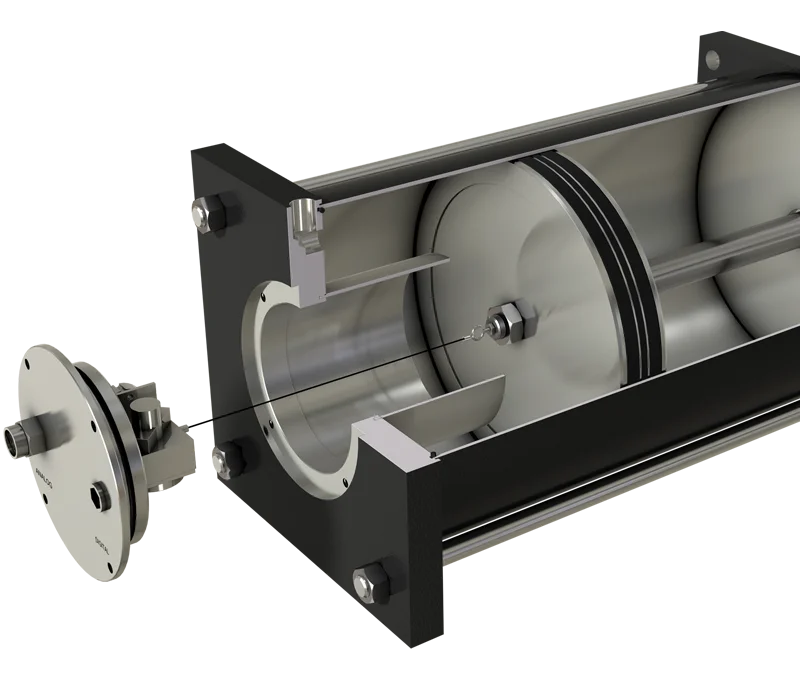

| Barrel | High-strength Carbon fiber barrel |

| Vibration resistance | up to 10Gs at 2000Hz |

| Stroke lengths | Made-to-order |

DESIGN PARAMETERS

| Protection Class | Meets NEMA 1, 3, 4, 6P and IEC IP67 |

|---|---|

| Cable Ratings | UL: ITC/PLTC/AWM, 105°C, 300 V CSA: CMX–OUTDOOR–CMG/AWM, 105°C, 300 V |

| Standard Temp | -20°C (-4°F) ~ 90°C (194°F) |

|---|---|

| Low Temp | -40°C (-40°F) ~ 90°C (194°F) |

Highlights

Design & Materials

Click on the (+) Icons to see more details.

Series AT Dart Valve Applications

Industries trust us to provide state-of-the-art actuation and automation solutions in the following sectors.

Oil and Gas

Empowering oil and gas operations with advanced valve automation, ensuring efficient flow control for upstream and downstream applications.

Chemical Processing

Maximizing chemical processing efficiency with cutting-edge automation and precision control technologies.

Mining & Processing

Boosting mineral processing productivity with innovative automation and control systems.

Water Treatment

Streamlining water treatment processes with advanced valve automation, such as regulating flow rates for precise flow control.

Power Generation

Enhancing power generation reliability through state-of-the-art valve automation, ensuring seamless operation of turbine control valves for optimized energy output.

Manufacturing

Revolutionizing manufacturing efficiency with precise actuation automation by optimizing the operation of advanced operations from aviation testing systems to industrial milling process control.

Datasheets & Videos

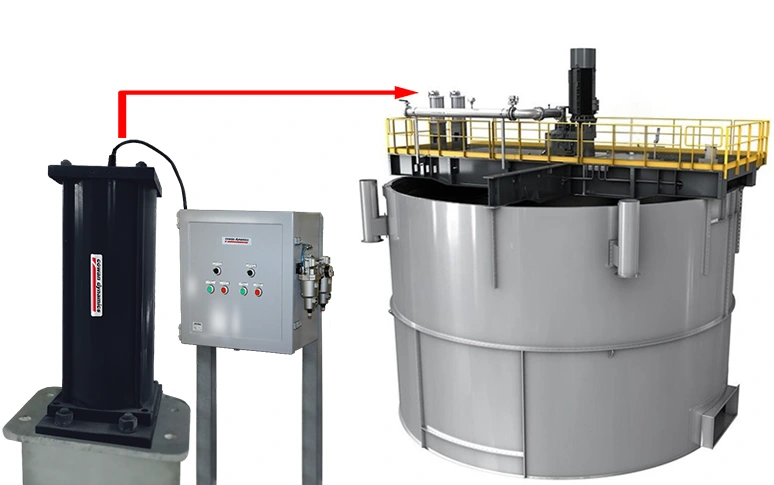

Remote Mount

Digital valve positioners mounted remotely in a cabinet are ideal for harsh environments and any application with difficult or limited access to the actuator. Cabinets available: NEMA 4/4X or for hazardous areas. Manual override customized to suit your application.

Direct Mount

No mechanical linkage requirement gives you the flexibility to mount directly on the actuator or the valve in any orientation.

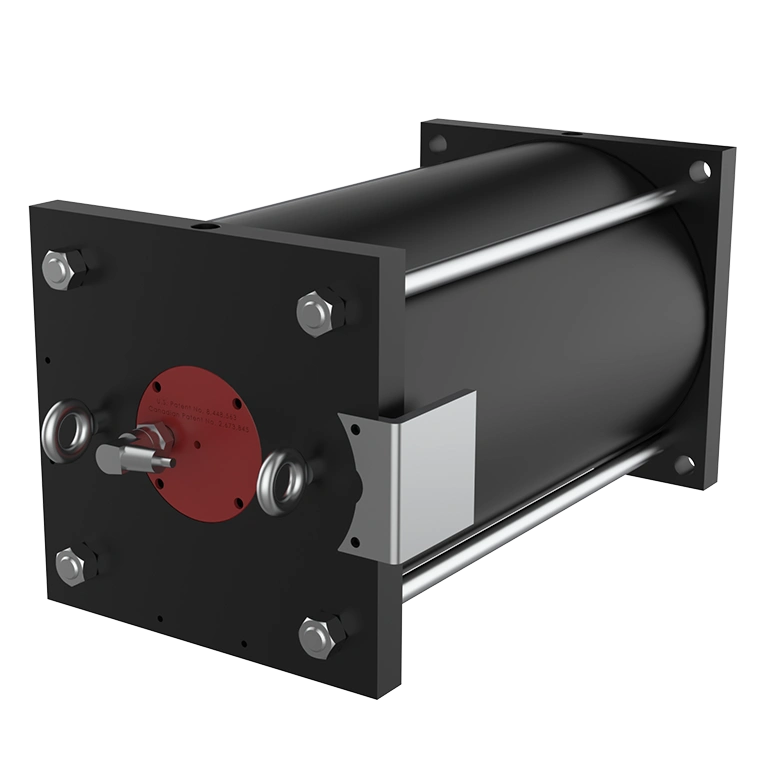

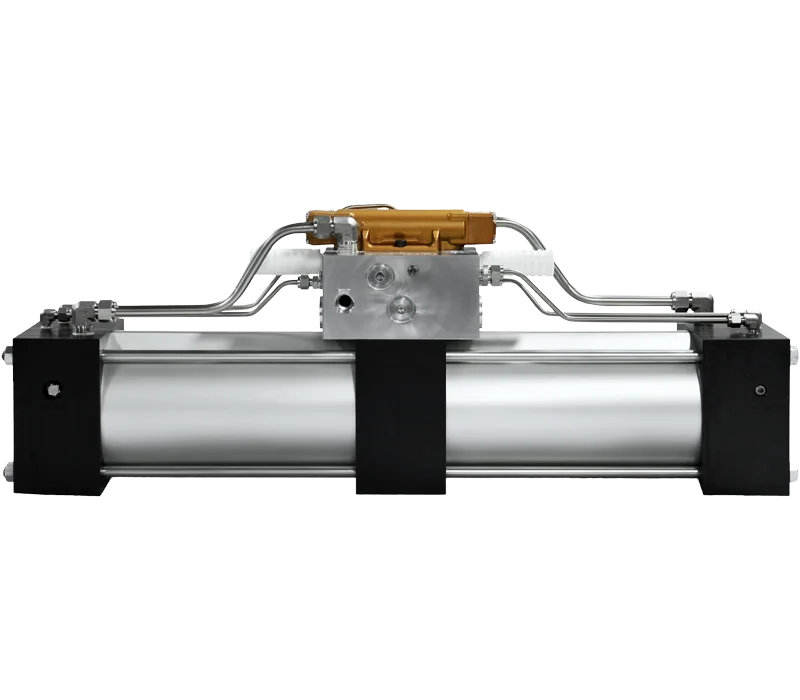

A2A Booster

A2A Systems are significantly smaller and lighter than a conventional air tank system. They are up to 85% smaller and up to 45% lighter providing a more economical solution.

Volume Booster

Volume boosters are recommended with larger modulating actuators for smooth operations. Typically required for 10″ bore and above. Booster can be installed either directly on the AT or in a remote panel.

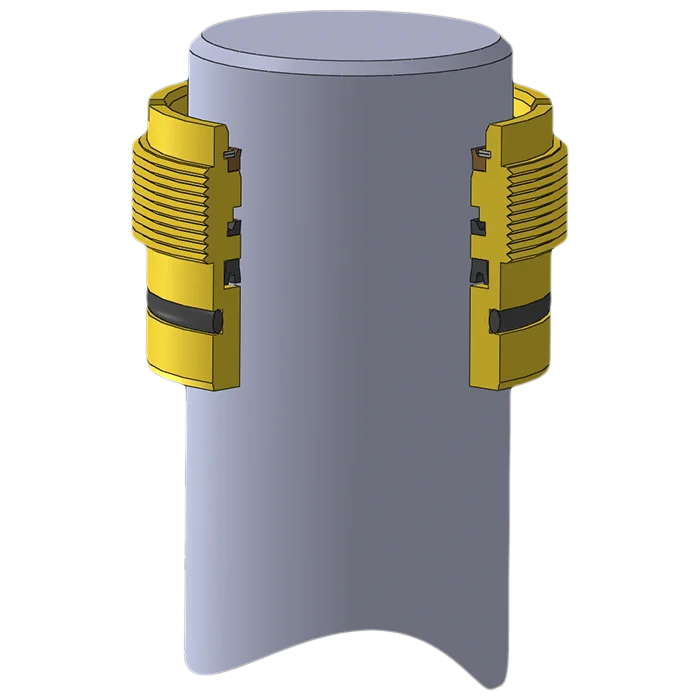

GT3 Gland for Harsh Environments

Triple-seal gland with dual wipers. Rugged metallic scrapper and urethane double-acting wiper deflect contamination away from the rod seal for long service life.

Low Temp

Cast Iron construction for applications where yellow metals are not allowed.

Remote Mounts

Digital positioners mounted remotely in a cabinet are ideal for harsh environments and any application with difficult or limited access to the actuator. Cabinets available: Nema 4X, 9X and explosion-proof, manual override customized to suit your application

Direct Mounts

- Direct mount digital positioner

- NEMA 4X/IP66

- Fail/close or Open Upon Loss of Power

- Optional Fail Last Module

- Communication options:

- 4-20 mA

- HART

- Profibus PA

- Foundation Fieldbus

- Intrinsically safe version available

AT Series Dart Valves were installed in an operating the Sag Mill discharge. The flotation cells featured Cowan’s patented AT Series Dart Valve actuators and control panels.