Anti-surge Valve Actuator

Specifications

| Supply | Pneumatic power supply |

|---|---|

| Control | Pneumatic controls |

| Remote Options | Remote electro-pneumatic controls |

| Thrust | Up to 425,000 lbs |

| Stroke Time | 0.5 secs |

| Failure Mode | Immediate failure actions |

| Dead Time | 0.3 seconds |

| Overshoot | 0.4 of 1% of the stroke |

| Supply | Electric power supply |

|---|---|

| Control | Electro-Hydraulic controls |

| Remote Options | Local and remote controls, Programable PLC |

| Thrust | Up to 588,000 lbs |

| Stroke Time | 0.5 secs |

| Failure Mode | Immediate failure actions |

| Dead-band | Adjustable down to 0.1% of stroke |

| Power Consumption | Low |

Highlights

Design & Materials

Click on the (+) Icons to see more details.

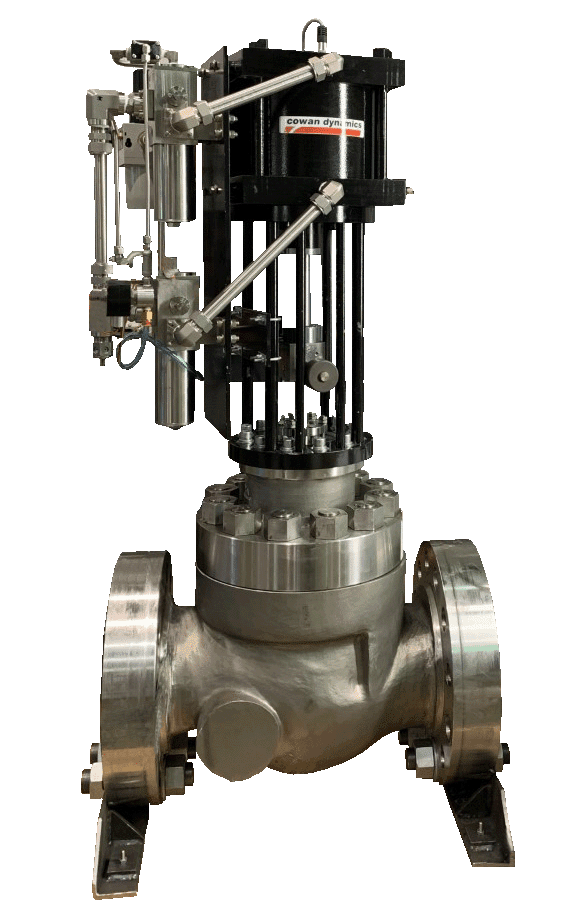

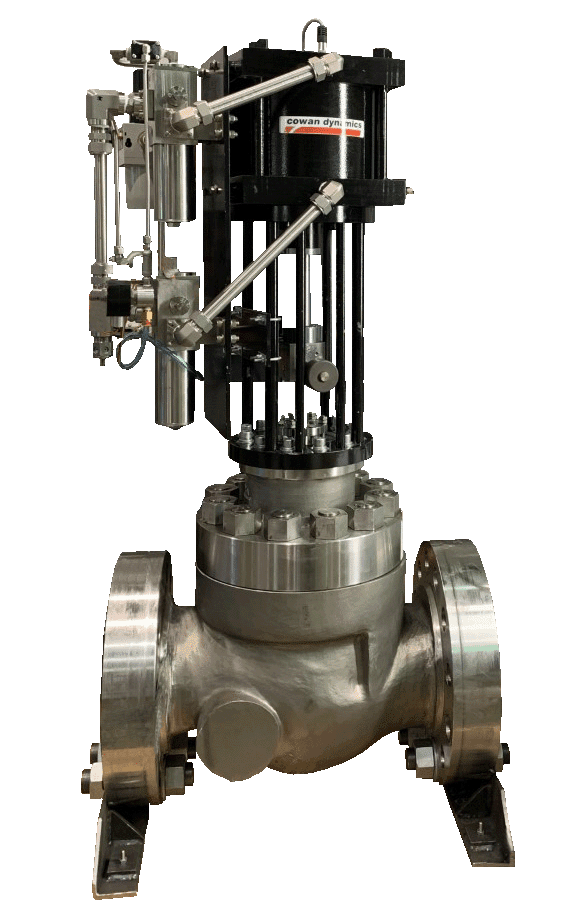

Pnuematic Anti-Surge Valve Actuator System

Position Transducer |

Linkage-less connection to the positioner

Pilot Valves

Fail-safe System |

Solinoid Valve

Volume Booster

Pilot Valves

Volume Booster

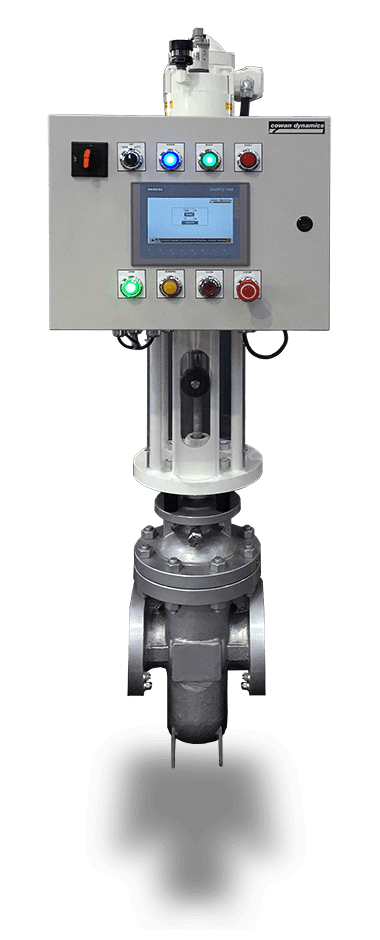

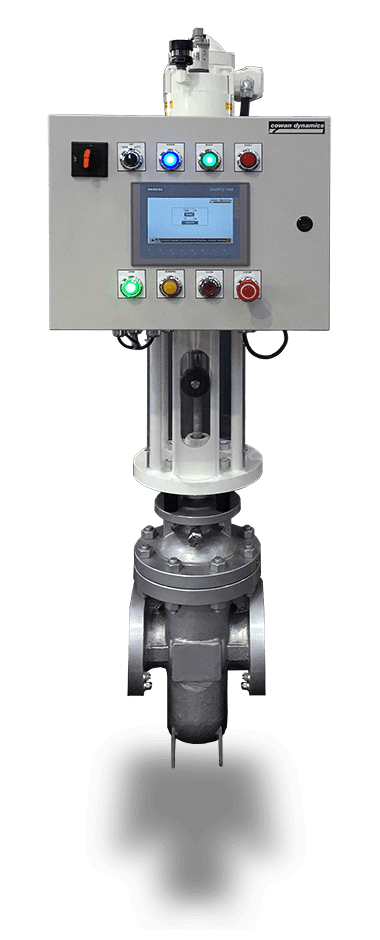

Electro-hydraulic Anti-Surge Valve Actuator

Compact Design | All in one design. No need for separate hydraulic power units and hoses.

Easy-to-Use Display | The large, easy-to-use touchscreen display makes it easy to set up and operate. The software logs the real-time valve performance analysis.

Versatile Modes | The E2H provides Fail Last, Fail Close, and Fail Open modes. It also has the ability to be mounted in horizontal and vertical positions.

Linear Valve Actuator | The linear valve actuator offers up to 500,000 Lbf of Thrust.

Anti-surge Valve Actuator Applications

Industries trust us to provide state-of-the-art actuation and automation solutions in the following sectors.

Oil and Gas

Empowering oil and gas operations with advanced valve automation, ensuring efficient flow control for upstream and downstream applications.

Chemical Processing

Maximizing chemical processing efficiency with cutting-edge automation and precision control technologies.

Mining & Processing

Boosting mineral processing productivity with innovative automation and control systems.

Water Treatment

Streamlining water treatment processes with advanced valve automation, such as regulating flow rates for precise flow control.

Power Generation

Enhancing power generation reliability through state-of-the-art valve automation, ensuring seamless operation of turbine control valves for optimized energy output.

Manufacturing

Revolutionizing manufacturing efficiency with precise actuation automation by optimizing the operation of advanced operations from aviation testing systems to industrial milling process control.

More Information

In simple terms, surge in a compressor is the phenomenon that occurs when the flow through the entire compressor is reversed intermittently.It is critical to avoid this phenomenon from happening since it is catastrophic for the integrity of the compressor as it will severely damage it. to prevent surges from happening, systems normally use anti-surge valves.

For such critical operation, the valve must be completed with controllers that use the suction and discharge pressure and temperatures to determine the flow at which the condition of surge will occur.It is crucial for such valves to be operated by actuators that can achieve extremely fast stroking times, high frequency of operation, minimal dead time and overshoot.

Depending on the availability and reliability of the power supplies sources of your application, Cowan Dynamics has developed solutions within our product lines of Pneumatic and Electro-hydraulic actuators that allow opening times as fast as 0.5 secs, dead time of 0.3 seconds and an overshoot of 0.4 of 1% of the stroke.

Our team of technical experts can assist you to select the best solution for your application.