FCS SeriesAir-Spring Fail-Safe Systems

Safe. Effective. Reliable. Air-Spring Fail-Safe Systems for Mission-Critical Close/Open Valve Applications.

Specifications

Overview

| Fail Modes | Fail Open, Close, Last or Lock |

|---|---|

| Applications | Suitable for All Types of Linear and 1/4-Turn Actuators |

| Custom Design Specs | Individually Designed to Meet Specific Requirements |

| Environment | Engineered for All Types of Environments |

Highlights

Air-Spring Fail-Safe Systems

Cowan Dynamics air-spring systems provide a reliable solution for large or high-pressure valve applications in which conventional spring-return cylinders are not a mechanically or economically viable option. Designed to trigger a fail-open, fail-close or fail-last condition in the event of loss of power, air supply, or both; fail-safe systems prevent unwanted system conditions from occurring during emergency situations.

Each fail-safe system is engineered to meet your site-specific process control requirements and operating challenges

Automated, fully integrated control elements ensure fail-safe protection with little or no maintenance

Fully enclosed control panels withstand the harshest operating or environmental conditions

Panels can be padlocked to prevent unauthorized access

World-renowned for their durability, Cowan systems are built to provide years of service.

Comparison

Click on the (+) Icons to see more details.

Conventional System |

- 785 lbs

- 400 Gallon Tank

- 30″ x 30″ Footprint

- 20″ Bore Pneumatic Valve Actuator

Space & Cost Saving |

- up to 85% Smaller

- up to 45% Lighter

- up to 40% Cost Savings

The A2A System |

- 430 lbs

- 60 Gallon Tank

- 20″ x 20″ Footprint

- 16″ Bore Pneumatic Valve Actuator

FCS Series Applications

Industries trust us to provide state-of-the-art actuation and automation solutions in the following sectors.

Oil and Gas

Empowering oil and gas operations with advanced valve automation, ensuring efficient flow control for upstream and downstream applications.

Chemical Processing

Maximizing chemical processing efficiency with cutting-edge automation and precision control technologies.

Mining & Processing

Boosting mineral processing productivity with innovative automation and control systems.

Water Treatment

Streamlining water treatment processes with advanced valve automation, such as regulating flow rates for precise flow control.

Power Generation

Enhancing power generation reliability through state-of-the-art valve automation, ensuring seamless operation of turbine control valves for optimized energy output.

Manufacturing

Revolutionizing manufacturing efficiency with precise actuation automation by optimizing the operation of advanced operations from aviation testing systems to industrial milling process control.

Datasheets & Videos

In Market

- 150 psi Pneumatic Valve Actuator with integrated position transducer. Fully enclosed feedback unit is protected from damage. No exposed transducer or linkage arms. Excellent for flotation systems

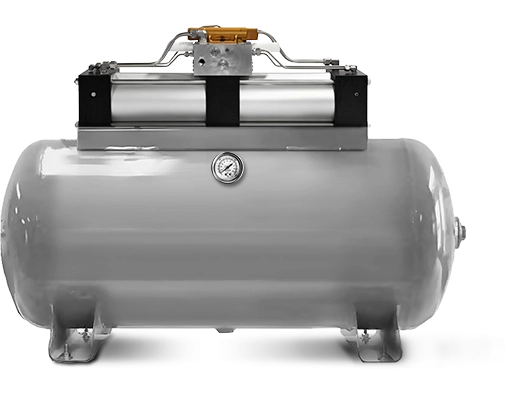

Basic Fail-Safe Systems

Basic air-spring systems include an air tank and pneumatic controls sized and configured to meet specific application needs.- Air tanks are ASME stamped and available with 20 to 5,000 gallon capacity

- Components are selected based on site-specific requirements: available air pressure, temperature and pressure range, cycle time, number of actuators, number of strokes, etc.

- For harsh environments, the control instruments can be housed in a protective enclosure

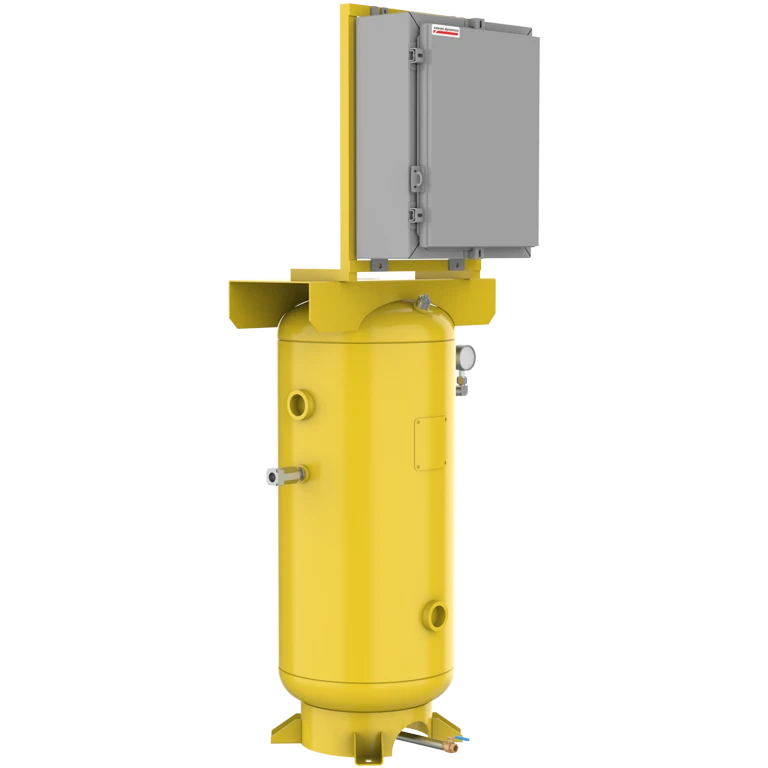

Boosted Fail-Safe Systems

Consisting of a basic system to which a Cowan A2A pneumatic booster is added, these systems are designed for applications in which the available air pressure is too low and where space for additional air tanks is limited.- Cowan’s A2A pneumatic boosters intensify the pressure of the available air supply without the need for additional mechanical or electrical input

- Available in 2:1, 3:1, or 4:1 ratios

- Do More With Less: Smaller footprint of the entire fail-safe system allows users to reduce the actuator size, by increasing the operating pressure