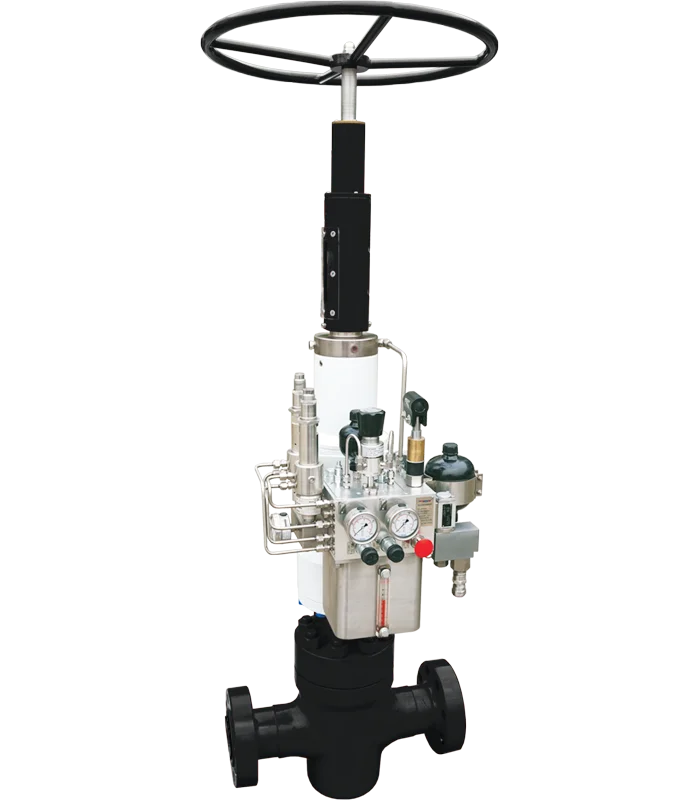

C6A SeriesAPI 6A Hydraulic Actuator

Designed and engineered for severe-service valve automation applications. The API 6A Hydraulic actuator has nominal pressures of 3,000 PSI / 5,000 PSI.

Specifications

Specification Overview

| Nominal Pressure | 3000 psi / 5000 psi |

|---|---|

| Standard Temperature | -40°C (-40°F) ~ 70°C (158°F) |

| Closing Time | < 5s |

| Solenoid Valve | 24 VDC, 10W |

Design Parameters

| API Specification | ISO 10423 / API 6A |

|---|---|

| Certification Number | 6A-1377 |

| Pressure Rating | 5000 psi |

| Temperature Ratings | L + U |

| Material Class | AA |

| Performance Requirement | Pr2 |

| Product Specification Level | PSL2 |

Reference Chart

| Valve DN | API Pressure Class (psi) | Stroke Length (in) | Model |

|---|---|---|---|

| 2 9/16 | 5,000 | 2.99 | C6A-100A |

| 2 9/16 | 10,000 | 2.99 | C6A-125A |

| 2 9/16 | 15,000 | 2.99 | C6A-125A |

| 3 1/8 | 5,000 | 3.78 | C6A-125A |

| 3 1/16 | 10,000 | 3.78 | C6A-125A |

| 3 1/16 | 15,000 | 3.78 | C6A-125B |

| 4 1/16 | 5,000 | 4.53 | C6A-125B |

| 4 1/16 | 10,000 | 4.65 | C6A-125B |

| 4 1/16 | 15,000 | 4.96 | C6A-125B |

| 5 1/8 | 5,000 | 5.91 | C6A-160 |

| 7 1/16 | 5,000 | 8.11 | C6A-200 |

| 7 1/16 | 10,000 | 8.15 | C6A-200 |

Options

| Fusible Plug | Quickly trips circuit to shutdown position when exposed to the rising temperature of fire |

|---|---|

| PSL/PLH | Customer preferred models can be promptly associated into the circuit onboard the manifold or pipeline to provide automatic operation of the shutdown system |

| Solenoid Valve | With low power consumption coils to provide efficient remote control of the shutdown system |

| Limit Switch | Valve open and close position with local indication and remote feedback |

| Isolating Valve | Specially designed to forestall ice blockage of moist gas under low temperature |

| Gate Valve | Ideally suited for on/off service |

| Self-Contained ESD System | Provides reliable valve shutdown capabilities when an external power source is either not available or not dependable |

| Hand Wheel | Manually operating when the hydraulic system is unavailable |

| Standard Temp | -40°C (-40°F) ~ 70°C (158°F) |

|---|

Highlights

The Self-Contained ESD System of the API 6A Hydraulic Actuator is a safety system that is designed to provide reliable valve shutdown capability when an external power source is either not available or not dependable. Using a hand pump with different control parts, a zero leakage circuit is maintained to ensure valve movement does not inadvertently occur until a fail-safe signal is received.

The Self-Contained ESD System, with its sequence valve and bypass valve, can directly pressurize and open the valve conveniently in spite of external conditions.

All control system components of the hydraulic actuator are integrated into one manifold, with all channel connections among each part designed within the module. The structure is compact, reliable and no leakage even in extremely high or low ambient temperature.

Temperature compensation of high pressure hydraulic actuator circuit and low pressure control circuit is accomplished with two separate accumulators. This assures system stability by minimizing relief valve operation and eliminating valve drift due to large temperature changes.

Specialized troubleshooting design provides a quick self-diagnosis system.

With volume compensating design, the hydraulic control loop is totally isolated with air, avoiding deterioration or contamination of the hydraulic oil. The C6A can be installed at any angle necessary.

Design & Materials

Click on the (+) Icons to see more details.

Series C6A Applications

Oil and Gas

Empowering oil and gas operations with advanced valve automation, ensuring efficient flow control for upstream and downstream applications.

Chemical Processing

Maximizing chemical processing efficiency with cutting-edge automation and precision control technologies.

Mining & Processing

Boosting mineral processing productivity with innovative automation and control systems.

Water Treatment

Streamlining water treatment processes with advanced valve automation, such as regulating flow rates for precise flow control.

Power Generation

Enhancing power generation reliability through state-of-the-art valve automation, ensuring seamless operation of turbine control valves for optimized energy output.

Manufacturing

Revolutionizing manufacturing efficiency with precise actuation automation by optimizing the operation of advanced operations from aviation testing systems to industrial milling process control.

Datasheets & Videos