Custom Control Panels and SystemsCoker Valve Automation

For over 30 years, we have manufactured control panels for automating Coker valves and actuators used in delayed coking unit refineries.

Custom Control Panel Services

Engineering and Design

Assembly

Programming

Factory & Site Acceptance Testing

Worldwide Industrial Certifications

Highlights

Delayed Coker Valve Automation Solutions

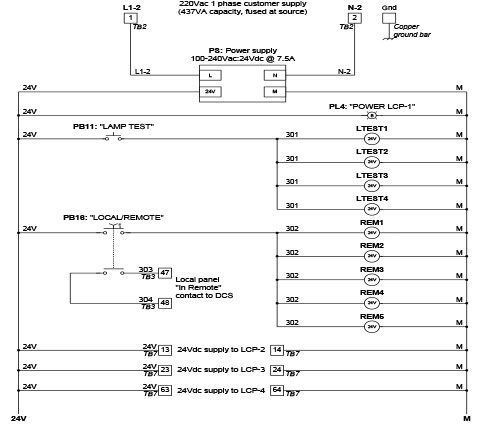

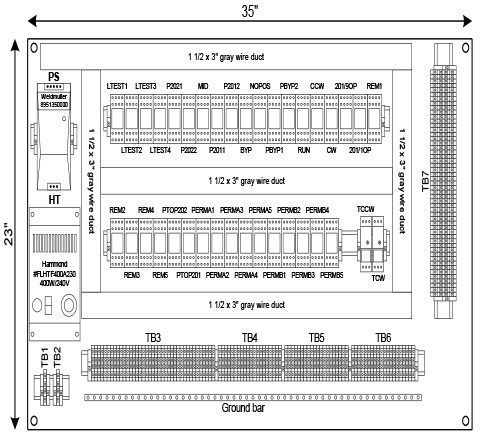

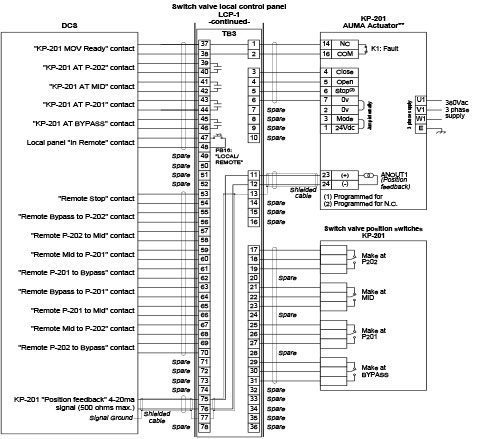

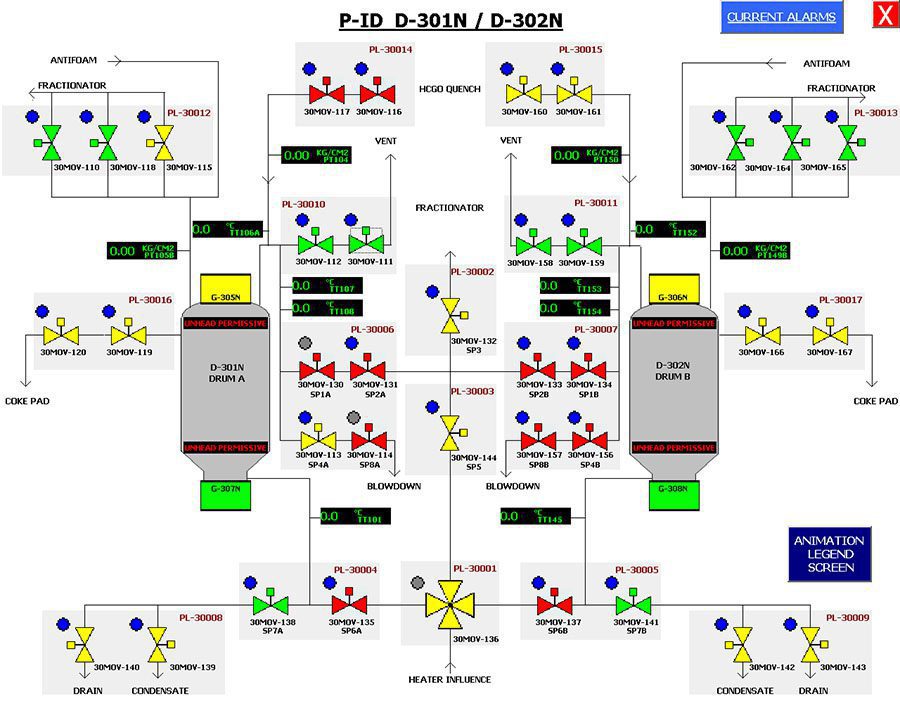

Cowan Dynamics supplied its first fully automated switch coker valve control system over 20 years ago for a delayed coker unit. Shortly after, Cowan manufactured a control panel that included interlocks to the inlet transfer line valves to avoid the pump’s dead-ending. Cowans’ coker unit control panels are designed with a comprehensive interlock system that allows for the automated operation of valves with a minimum of risk.

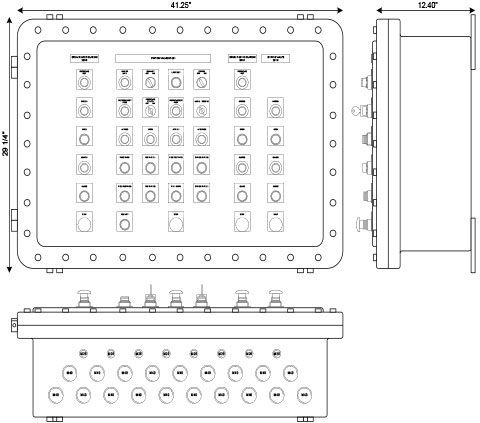

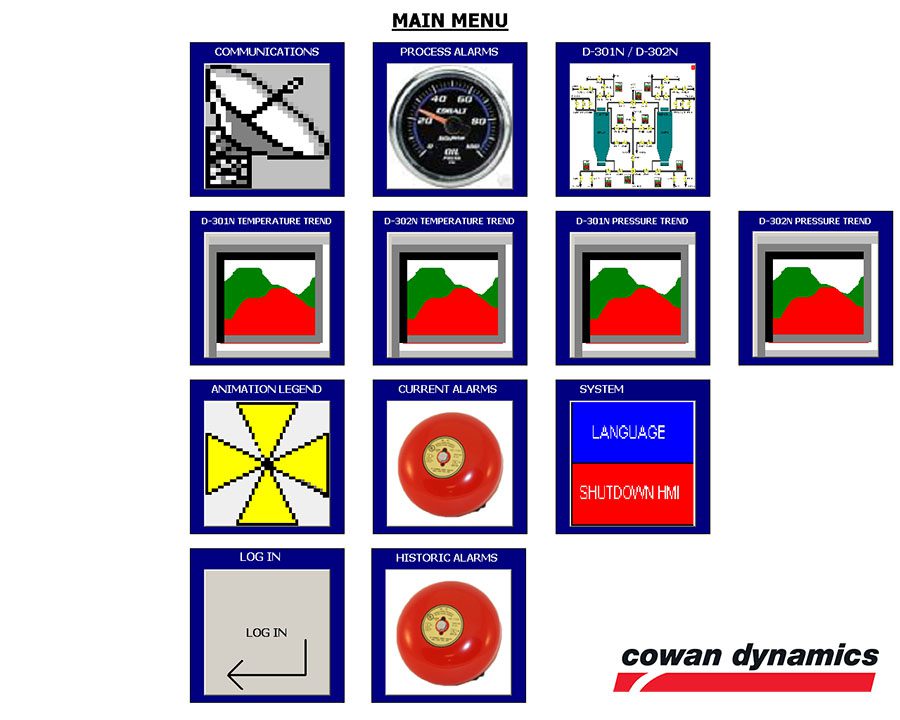

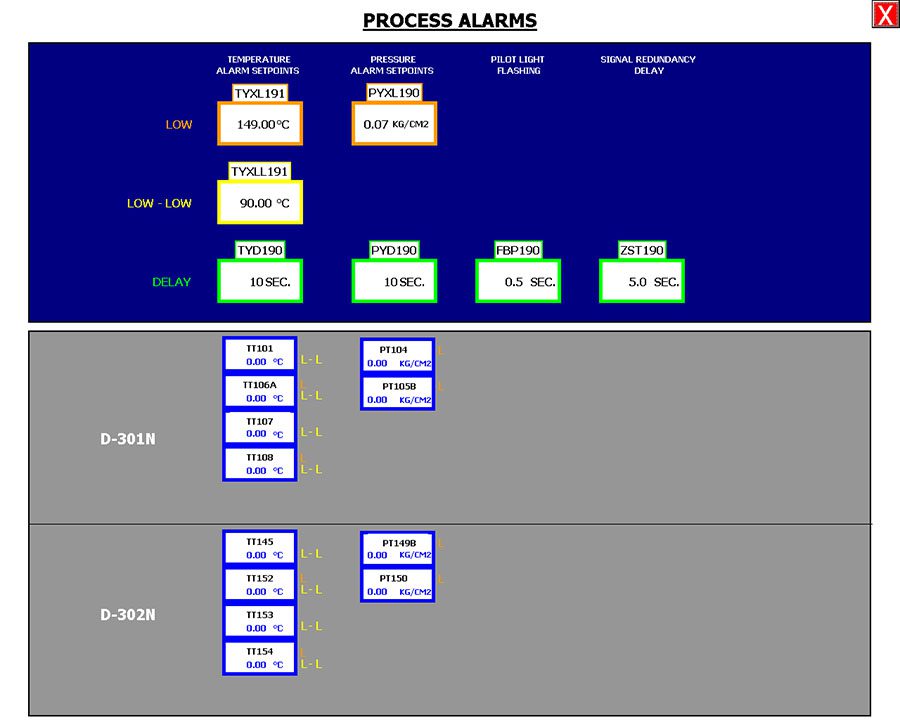

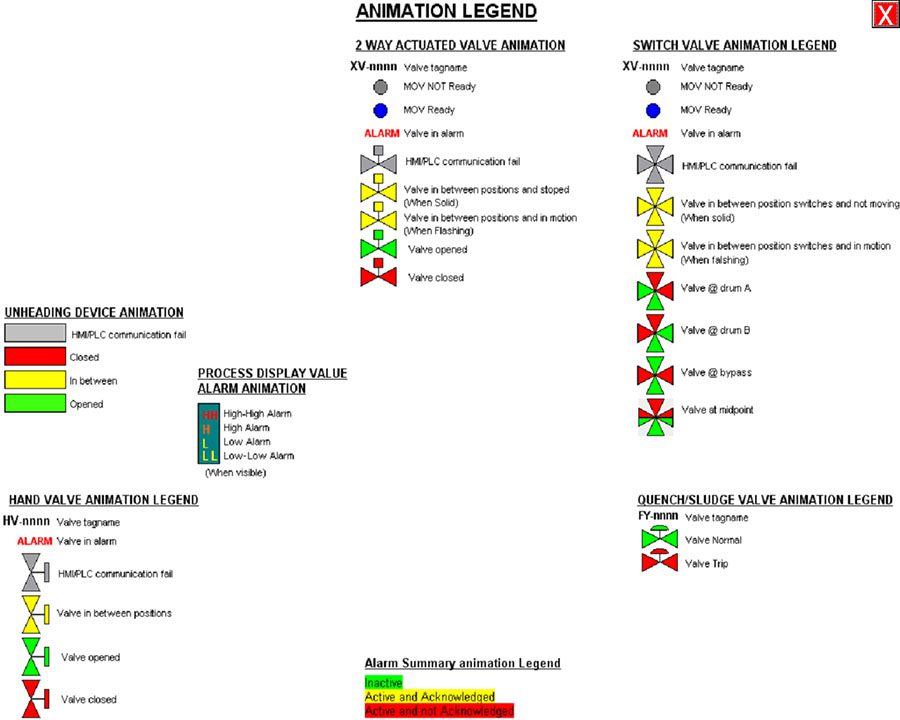

Cowan Dynamics provides turnkey delayed coker valve automation solutions that include intrinsically safe Ex I or flameproof Ex d panels, as well as SIL-3 rated valve actuators. Systems can be fully redundant and offer a variety of options, such as remote operation and diagnostics via touch screens HMI in the field

Cowan Dynamics specializes in complex integrations and is capable of offering a factory acceptance test (FAT) to ensure that coker valves, actuators, and panels works to specifications prior to shipment. End-users are often invited to attend testing of these systems at our factory or can remotely view the FAT process online.

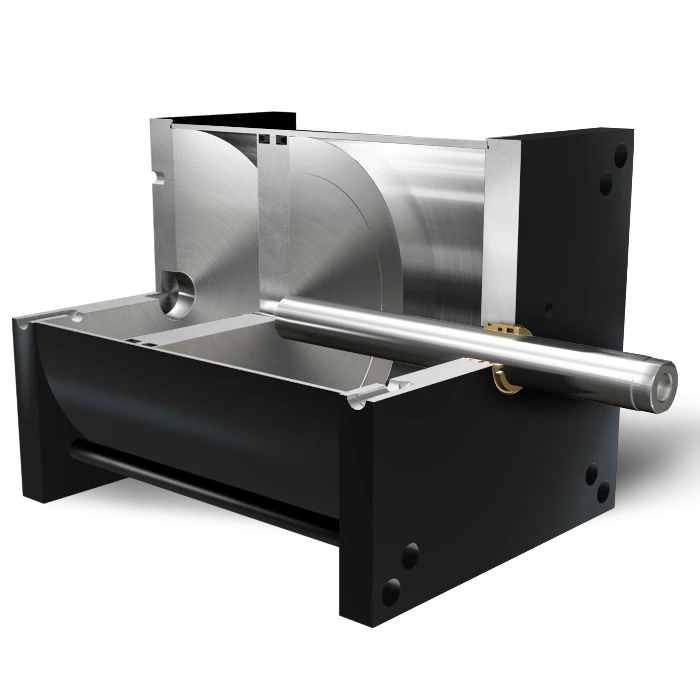

Design & Materials

Click on the (+) Icons to see more details.

Piston Packing

Nitrile U-Cup standard for long service life; High and Low Temp optional

High-Strength Composite Barrel

Light-weight, low-friction and corrosion-resistant.

Flange Mounting Hole

ISO/MSS Flange mounting holes See Actuator Dimensions Page for details

Cartridge Bushing

Allows for quick and easy rod seal replacement without disassembling the actuator

Rod Wiper

To prevent contamination inside the cylinder for long seal life. High or low temp optional

Gland Packing

Nitrile U-cup standard; High or low temp optional

Custom Control Panel Applications

Industries trust us to provide state-of-the-art actuation and automation solutions in the following sectors.

Oil and Gas

Empowering oil and gas operations with advanced valve automation, ensuring efficient flow control for upstream and downstream applications.

Chemical Processing

Maximizing chemical processing efficiency with cutting-edge automation and precision control technologies.

Mining & Processing

Boosting mineral processing productivity with innovative automation and control systems.

Water Treatment

Streamlining water treatment processes with advanced valve automation, such as regulating flow rates for precise flow control.

Power Generation

Enhancing power generation reliability through state-of-the-art valve automation, ensuring seamless operation of turbine control valves for optimized energy output.

Manufacturing

Revolutionizing manufacturing efficiency with precise actuation automation by optimizing the operation of advanced operations from aviation testing systems to industrial milling process control.

Solutions & Services