Cowan Dynamics

This article has been reviewed by Cowan Dynamics Application Engineering team. Contact Us and our application engineers will assist you with your application.

Valves are used to control the flow of fluids in process control applications by opening, closing, or partially obstructing the fluid flow and controlling the line pressure. Depending on the flow requirements of the industrial process system, some method of changing the positions of valves is needed. Some valves are controlled manually using handwheels or levers, while others require frequent opening, closing, or throttling. In such cases, manual operation becomes impractical. Instead of relying on hand-operated mechanisms, automated valve solutions, such as using a valve actuator, are used to efficiently position and control valves.

This Valve Actuator Selection Guide for 2025 covers actuator types, key selection factors, pros and cons, and the latest advancements to help you find the right solution for your application.

What is a valve actuator?

A valve actuator is a mechanical device that moves or regulates a control valve, eliminating the need for manual operation. By automating valve adjustments, actuators reduce the need for operators to physically reposition each valve.

When valve actuators are integrated into a system, they allow for remote operation, enabling control from locations such as a control room. These actuators ensure precise and rapid valve adjustments, enhancing efficiency and accuracy.

Control valve actuators are specifically used with throttling valves, which regulate fluid flow. Valves designed to automatically adjust flow rates are commonly referred to as control valves.

Valve Actuator Types & Common Applications

|

Actuator Type |

Power Source |

Mechanism |

Common Applications |

|---|---|---|---|

|

Compressed Air |

Uses air pressure to move a piston or diaphragm |

Fast operation, hazardous environments, oil & gas, water treatment |

|

|

Hydraulic Actuator |

Pressurized Hydraulic Fluid |

Uses hydraulic pressure to move a piston |

High-force applications, heavy-duty valves in oil & gas, marine, power plants |

|

Electric Actuator |

Electricity |

Uses an electric motor to drive gears or a screw mechanism |

Precise control, automation, remote operation in HVAC, water treatment, and manufacturing |

|

Manual Actuator |

Manual (Hand) |

Operated by a handwheel, lever, or gearbox |

Simple on/off control, backup operation in industrial and utility applications |

|

Spring Return Actuator |

Pneumatic, Hydraulic, or Electric |

Uses an internal spring to return the actuator to a default (fail-safe) position |

Safety applications. |

|

Scotch Yoke Actuator |

Pneumatic or Hydraulic |

Converts linear motion into high torque rotary motion using a yoke mechanism |

High-torque quarter-turn applications such as large ball and butterfly valves |

|

Rack and Pinion Actuator |

Pneumatic or Hydraulic |

Piston-driven rack rotates a pinion gear for rotary motion |

Compact rotary operation, small to medium-sized ball, plug, and butterfly valves |

|

Linear Actuator |

Electric, Pneumatic, or Hydraulic |

Moves a valve stem in a straight line (linear motion) |

Control valves, gate valves, globe valves in process industries |

|

Rotary Actuator |

Electric, Pneumatic, or Hydraulic |

Provides rotary motion for quarter-turn or multi-turn valves |

Used in ball, plug, and butterfly valves in automation and industrial applications |

|

Electro-Hydraulic Actuator |

Electricity & Hydraulic Fluid |

Uses an electric motor to generate hydraulic pressure for motion |

Combines precision and high force, ideal for remote operations in oil & gas, offshore drilling, emergency shutdown (ESD) valves. |

|

Diaphragm Actuator |

Pneumatic or Hydraulic |

Uses a flexible diaphragm to convert air or hydraulic pressure into linear motion |

Control valves in chemical processing, food and beverage, pharmaceuticals |

Key takeaways:

-

The 3 most common actuators are Pneumatic, hydraulic, and electric are the primary types of actuators.

-

Scotch yoke and rack-and-pinion are subtypes of rotary actuators commonly used for quarter-turn valves.

-

Spring return actuators are used for fail-safe applications.

-

Electro-hydraulic actuators are hybrid systems combining electric and hydraulic benefits.

Power Source – Pneumatic or Hydraulic or Electricity

Air Pressure (Pneumatic Systems)

Pneumatic Systems (Air pressure) relies on compressed air to generate motion and is typically used in pneumatic actuators systems. It operates at lower pressures (usually 80-100 PSI) and is ideal for fast, repetitive movements.

Hydraulic Pressure (Hydraulic Systems)

Hydraulic pressure uses pressurized fluid to generate force, providing higher power output than air pressure. These systems operate at much higher pressures (1,000-5,000 PSI or more) and are ideal for heavy-duty applications. Hydraulic systems are best suited for applications requiring high force and precision, such as lifting heavy loads or controlling large industrial machinery.

Electricity

Electricity powers both electric and electrohydraulic actuators, offering precise and automated control for industrial applications.

Control Valve Classification: Linear vs. Rotary

Control valves are classified based on their motion: linear or rotary (quarter turn-valves). Each type of valve operates differently and requires specific actuators to regulate valve position effectively.

Linear Control Valves

Linear control valves operate by moving the valve stem in an up-and-down motion to control flow. These valves are commonly actuated using piston actuators or diaphragm actuators, which convert force into linear displacement. A pneumatic signal is often used in pneumatic actuators, allowing air pressure to drive the actuator and precisely position the valve. An example is a globe valve, which provides precise flow regulation in industries such as oil & gas, chemical processing, and water treatment.

Rotary Control Valves

Rotary control valves function with a 1/4 turn (90-degree rotation), adjusting the valve open or closed state. These valves use pneumatic, electric, or hydraulic rotary actuators, which apply torque to rotate the valve stem. A common example is a ball valve, which allows for quick shutoff by turning the ball inside the valve body, making it ideal for high-speed isolation applications.

Pros & Cons of Valve Actuator Types

When choosing between the four main types of valve actuators—pneumatic, hydraulic, electro-hydraulic, and electric—weighing their pros and cons to determine the best fit for your application.

Pneumatic Valve Actuators

Pneumatic valve actuators utilize air pressure to generate motion, allowing precise valve positioning. They are the most widely used actuator type in process systems due to their reliability and efficiency. These actuators operate efficiently with a reliable air supply, which is essential for consistent performance.

By converting air pressure into mechanical motion, pneumatic actuators provide fast and precise valve control, making them ideal for industries like oil and gas, water treatment, and chemical processing. Their simple design and dependability make them a preferred choice for automation in environments where electrical actuators may not be suitable.

Pros

-

Lowest cost

-

Most cost-effective actuator from a purchase point of view

-

Fast-acting, high speed

-

100% duty cycle

-

Simple to repair

-

Long-lasting

-

Simple to operate

Cons

-

Large & heavy – difficult to install in tight spaces

-

Requires expensive pneumatic air supply system that must be maintained

-

Not as accurate due to the compressibility of air

Hydraulic Actuator

Hydraulic actuators are powered by a pressurized liquid, such as hydraulic fluid, to generate high-force linear or rotary motion, making them ideal for heavy-duty industrial applications requiring precise control and reliability.

Pros

-

Fast-acting, high speed

-

100% duty cycle

-

Simple to repair

-

Long-lasting

-

Simple to operate

Cons

-

Requires expensive supply system that must be maintained.

Electric Actuators

Electric actuators, uses electricity to generate motion, either in a linear or rotary direction, to control valve positioning. In cases where continuous power is supplied, the electric actuators can hold the valve in the same position without requiring additional energy.

These electric actuators are commonly used in industrial automation, water treatment plants, HVAC systems, power generation, and process industries where precise and remote control of valves is needed.

Pros

-

Simple installation

-

Data logging options available

Cons

-

Slow

-

Limited duty cycle (typically less than 30%)

-

Not available for fail-safe applications

-

Difficult to repair

-

Fragile

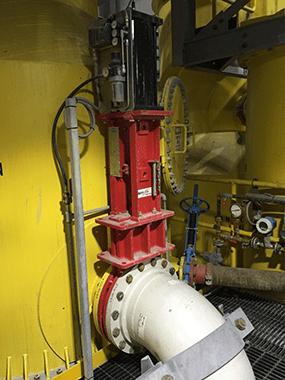

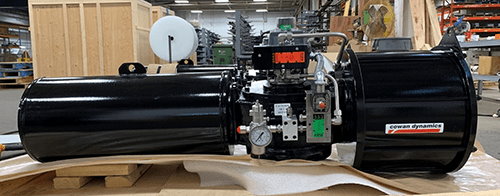

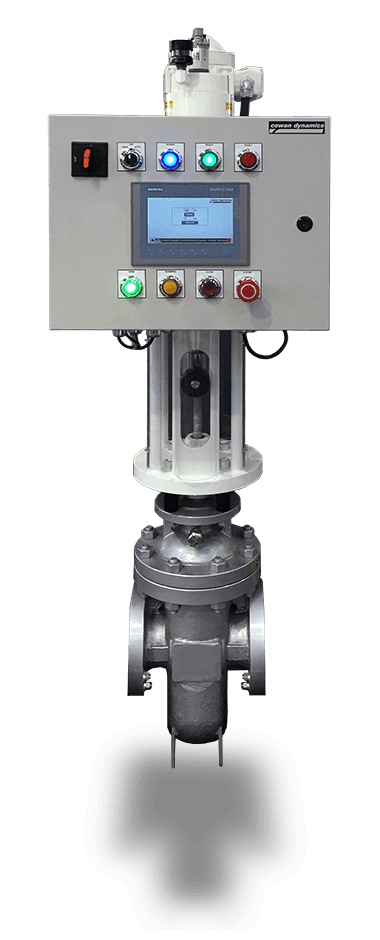

Electro-Hydraulic Actuator

Electro-hydraulic actuators (EHA) eliminate the need for large, separate hydraulic systems by incorporating control equipment into a compact, self-contained unit. These actuators function independently and are powered by electricity, providing efficient and reliable operation.

The actuator can be configured for safety fail positions depending on events like power failure, such as:

-

Fail Open

-

Fail last lock

-

Fail Close

Pros

-

Simple Installation – complex hydraulic supply system not required

-

100% Duty Cycle

-

Fail-safe capability

-

Remote Diagnostics/Data logging

-

Fast-acting, high speed

-

Highly accurate

-

Variable speed motor allows for custom open & closing times

-

Custom open & closing times can easily be set in the field

Cons

-

Most expensive option

-

Difficult to repair

Valve Actuator Standards

Industry standards play a crucial role in ensuring the performance, reliability, and safety of valve actuators in industrial applications. The International Society of Automation (ISA) and the International Organization for Standardization (ISO) have established various standards that govern the sizing, selection, testing, and operation of different types of actuators.

Various ISA Standard & ISO Standards for valve actuators include:

-

ISA96.01 -requirements for terminology for valve actuators and their accessories

-

ISA96.02 – requirements for electric actuators for both on-off duty and modulating applications

-

ISA96.03 defines the standards and requirements for pneumatic valve actuators, including both single-acting and double-acting types, specifically designed for on-off applications.

-

ISA96.05 – automated valve includes the following:

-

Limit switches and other monitoring devices

-

Air regulation and filtration system

-

-

ISO 22153:2020 outlines the standards and requirements for electric valve actuators used in both on-off and control valve applications. It provides detailed guidelines on classification, design, enclosure specifications, corrosion protection, and procedures for conformity assessment.