Why use a valve actuator limit switch?

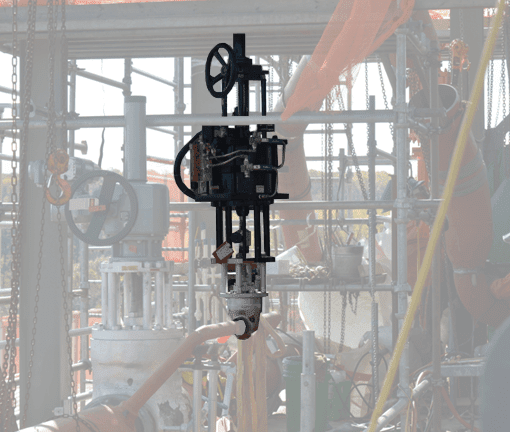

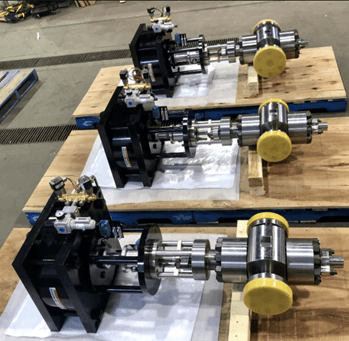

Valve automation is not simply the selection of the actuator. Control components are a big part of the complete actuation assembly. When looking into the components that a valve automation system must have, we normally see solenoid valves which are used to control the pressurized fluid into the actuator. In addition, we also see what we often call position limit switches. A valve actuator limit switch is a device that is designed to provide a remote signal to the control station, also known as PLC or DCS, regarding the valve position, often open or closed.

They can also be set to provide different position indications depending on the application. The switch will provide a signal on the position once the valve reaches it, therefore there will be a need for as many switches as position signals are required. For this reason valve actuator limit switches, used for valve position feedback, are often used for on/off applications for open or closed indication. Occasionally an additional switch is needed for partial stroke position testing.

There are different types of position switches or sensors for actuators such as mechanical switches, reed switches, solid-state switches, or proximity switches. Depending on the type of switch being used, some devices also include a visual indication so the operator can see the valve position through the remote signal and the valve for a local indication. Since limit switches are electrical devices, they must be classified depending on the area classification the valve and the actuator will be installed in. Material selection for the switches is also important if the valve will be installed in a corrosive environment.

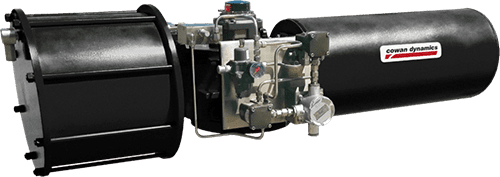

As valve automation experts, Cowan Dynamics can configure any of our valve actuators with limit switches to suit your application and the need for remote position signals.