Hydraulic Actuator

Our hydraulic actuators are built to deliver reliable performance across diverse industrial applications. From linear valve actuation in automated flow control systems to NFPA hydraulic cylinders for heavy-duty industrial motion control, we offer solutions that withstand even the most demanding environments.

Hydraulic Actuator Lineup

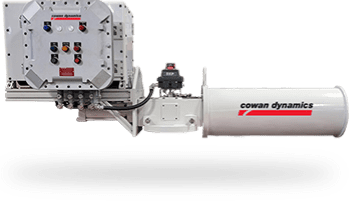

ML Series

Double-Acting Hydraulic Valve Actuator

Delivering thrust up to 1,500,000 lbs and SIL-3 Capable. Our double-acting hydraulic valve actuators are designed to suit a wide range of applications; from commodity to severe-service extremes.

- Bore Size: 1 1/2″ to 24″

- Configuration: Single-Stage

- Stroke Range: Up to 144″

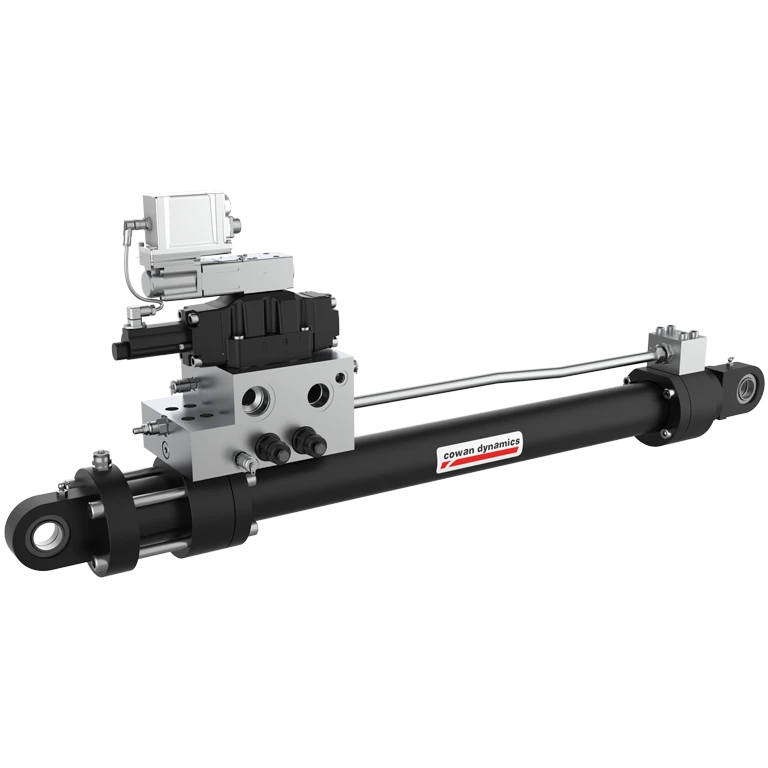

MS Series

Spring-Return Hydraulic Actuator

SIL 3 capable. Custom dimensional sizes and thrusts available. Springs are pre-compressed and seals in a factory-installed canister. Available in fail-open or fail-close.

- Thrust: up to 72,000 lbs

- Bore Size: 1 1/2″ – 14″

- Rod Size: 1″ – 7″

- Stroke Range: Up to 24″

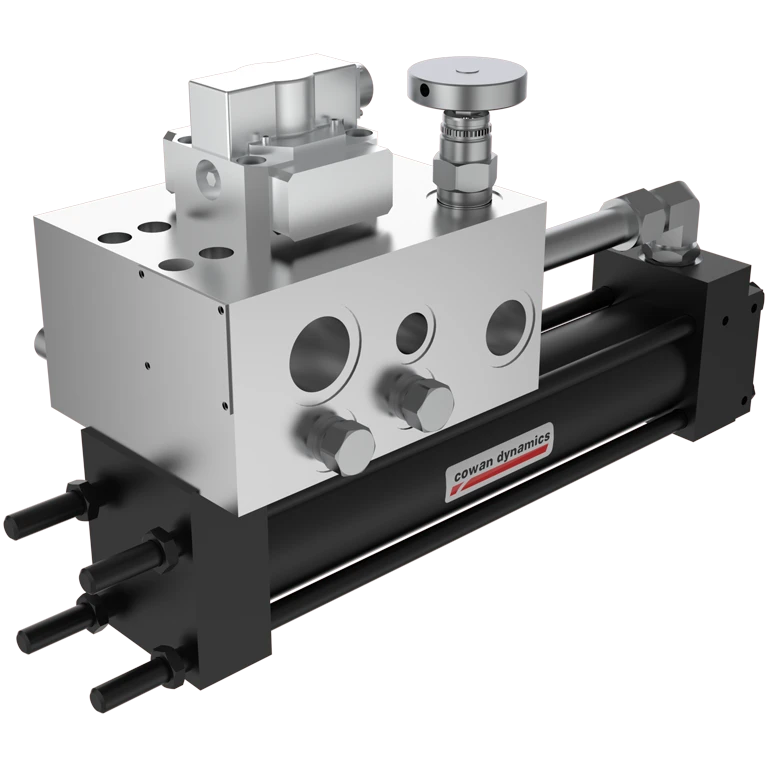

C6A Series

API 6A Hydraulic Valve Actuator

Designed and engineered for severe-service valve automation applications. The API 6A Hydraulic actuator has nominal pressures of 3,000 PSI / 5,000 PSI.

- Solenoid Valve: 24 VDC, 10W

- SPSL/PLH

- Self-Contained ESD System

ML Series

3000 PSI Hydraulic Cylinder

3000 PSI NFPA Hydraulic Cylinder with low friction high-speed seals. Triple-seal gland with dual wipers. 4 wrench flats on piston rod Retained bushing is removable without cylinder dis-assembly. Adjustable cushions available as an option Made-to-order stroke lengths.

- Piston rod diameter: 5/8″ to 10″

- Single-ended or double-ended

N Series

Medium Duty Hydraulic Cylinder

Medium Duty NFPA Hydraulic Cylinder built with a high-strength piston to rod joint. Dual-seal gland with removable cartridge rod bushing. Adjustable cushions available as an option.

- Made-to-order stroke lengths

- Check Valve Assembly

L Series

Hydraulic Servo Cylinder

L Series Servo Cylinder: Bore size range from 1.5” to 6”. Designed for the most demanding applications where position control is essential.

- Prepared to accept a linear displacement transducer

- Low friction high-speed seals

- Servo Hydraulic Cylinder

- Made-to-order stroke lengths

R3/R5 Series

Next Gen Mill-Type Cylinder

Designed in response to our customers’ need for a more durable, more reliable product to reduce their replacement and maintenance costs.

- Reduce design and development costs

- Custom mounts to suit any application

- Made-to-order stroke lengths

Hydraulic Actuator Applications

Oil and Gas

Empowering oil and gas operations with advanced valve automation, ensuring efficient flow control for upstream and downstream applications.

Chemical Processing

Maximizing chemical processing efficiency with cutting-edge automation and precision control technologies.

Mining & Processing

Boosting mineral processing productivity with innovative automation and control systems, like our dart valve automation products.

Water Treatment

Streamlining water treatment processes with advanced valve automation, such as regulating flow rates for precise flow control.

Power Generation

Enhancing power generation reliability through state-of-the-art valve automation, ensuring seamless operation of turbine control valves for optimized energy output.

Manufacturing

Revolutionizing manufacturing efficiency with precise actuation automation by optimizing the operation of advanced operations from aviation testing systems to industrial milling process control.

Learning Center

What Are Hydraulic Actuators?

Hydraulic actuators are essential devices used in industries requiring high force, precision control, and durability. They convert hydraulic power into mechanical motion, typically as linear actuators, which are widely used in heavy machinery, drilling rigs, and automation systems.

Industries like Oil & Gas, Mining, Power Generation, and Industrial Automation rely on hydraulic systems for their ability to handle extreme loads and operate in harsh environments.

Hydraulic vs. Pneumatic Actuators – A Key Comparison

While pneumatic actuators use compressed air, hydraulic actuators utilize hydraulic fluid, typically oil, to transfer energy. The main benefits of hydraulic actuators over pneumatics include:

✅ Higher force output for heavy-duty applications

✅ Greater control over speed and positioning

✅ More efficient power transmission with minimal energy loss

✅ Better suitability for extreme conditions, including high pressure and temperature

However, hydraulic actuators do have some inherent disadvantages, such as potential leaks and the need for maintenance to keep the system running efficiently.

Key Features of Hydraulic Actuators

✔ Power-dense design for high loads

✔ Control precision for industrial automation

✔ Resistance to harsh environments (mining, offshore rigs, and power plants)

✔ Long service life with proper maintenance

What Types of Hydraulic Actuators Used in Industrial Applications?

Single-acting and double-acting actuators (for push/pull applications)

Rack and pinion actuators (for rotary motion)

High-force actuators for mining and drilling applications

Automation actuators for robotic and manufacturing systems

Common Applications Across Industries

Oil & Gas: Valve actuation, drilling rigs, offshore platforms

Mining: Hydraulic shovels, haul truck braking systems, conveyor belt control

Power Generation: Turbine control, dam gate operation, nuclear reactor control

Industrial Automation: Robotics, CNC machinery, factory automation

Common Issues and Maintenance for Hydraulic Actuators

Regular maintenance helps prevent failures and ensures long-term reliability for hydraulic actuators or cylinders.

Common Issues and Their Causes

- Hydraulic Fluid Leaks: Caused by worn seals, cracked hoses, or excessive pressure.

- Loss of Power or Force: Due to low fluid levels, air in the system, or worn piston seals.

- Erratic Movement: Often results from contaminated fluid, faulty control valves, or air bubbles.

- Overheating: Caused by excessive pressure, poor cooling, or degraded hydraulic fluid.

- Slow Response Time: This can be due to clogged hydraulic lines, weak pumps, or dirty filters.

- Internal Leakage: This happens when piston seals wear out, or cylinder walls get damaged.

- Noisy Operation: This may result from cavitation, worn pumps, or loose components.

Essential Maintenance Practices

- Check and refill hydraulic fluid to maintain proper pressure.

- Inspect and replace seals, hoses, and fittings to prevent leaks.

- Monitor actuator performance for slow movement or power loss.

- Keep the system clean by replacing filters and preventing contamination.

- Ensure proper cooling and pressure settings to avoid overheating.

Regular maintenance minimizes downtime and maximizes the efficiency of hydraulic systems in industrial environments.

Technical Support and Training

At Cowan Dynamics, we understand the importance of technical support and training in ensuring the optimal performance of our hydraulic actuators. Our technical support team is available 24/7 to assist with any technical issues or concerns. We also offer comprehensive training sessions, both online and offline, to educate our customers on the use and maintenance of our products. By providing ongoing support and education, we help our customers maximize the lifespan and efficiency of their hydraulic systems.

About Cowan Dynamics

Cowan Dynamics is a leading manufacturer of hydraulic actuators and electro-hydraulic systems. Our products are designed to provide the highest level of performance, reliability, and efficiency. We offer a wide range of hydraulic actuators, including linear actuators, scotch yoke actuators, and custom-designed actuators. Our team of experienced engineers and technicians is dedicated to providing the best possible solutions for our customers’ hydraulic needs. With a commitment to innovation and customer satisfaction, Cowan Dynamics continues to set the standard in the hydraulic actuator industry.