Cowan Dynamics

This article has been reviewed by Cowan Dynamics Application Engineering team. Contact Us and our application engineers will assist you with your application.

In this article, you will learn about the various applications for knife gate valves & knife gate valve actuators. Knife gate valves are linear valves in which the closing membrane is a gate that is sharpened to better cut through the process media (such as slurry). The gate is connected to a stem and travels inside the valve body in which scrappers are often included to clean the gate as it moves from open to closed. They can be manual or automated (knife gate valve actuator), with metal or resilient seats, bi-directional, and come in wafer, lug and flange connections. Knife gate valves are very versatile and can be used in both isolation and control applications. However, to provide good control characteristics the valve trims must be custom-made.

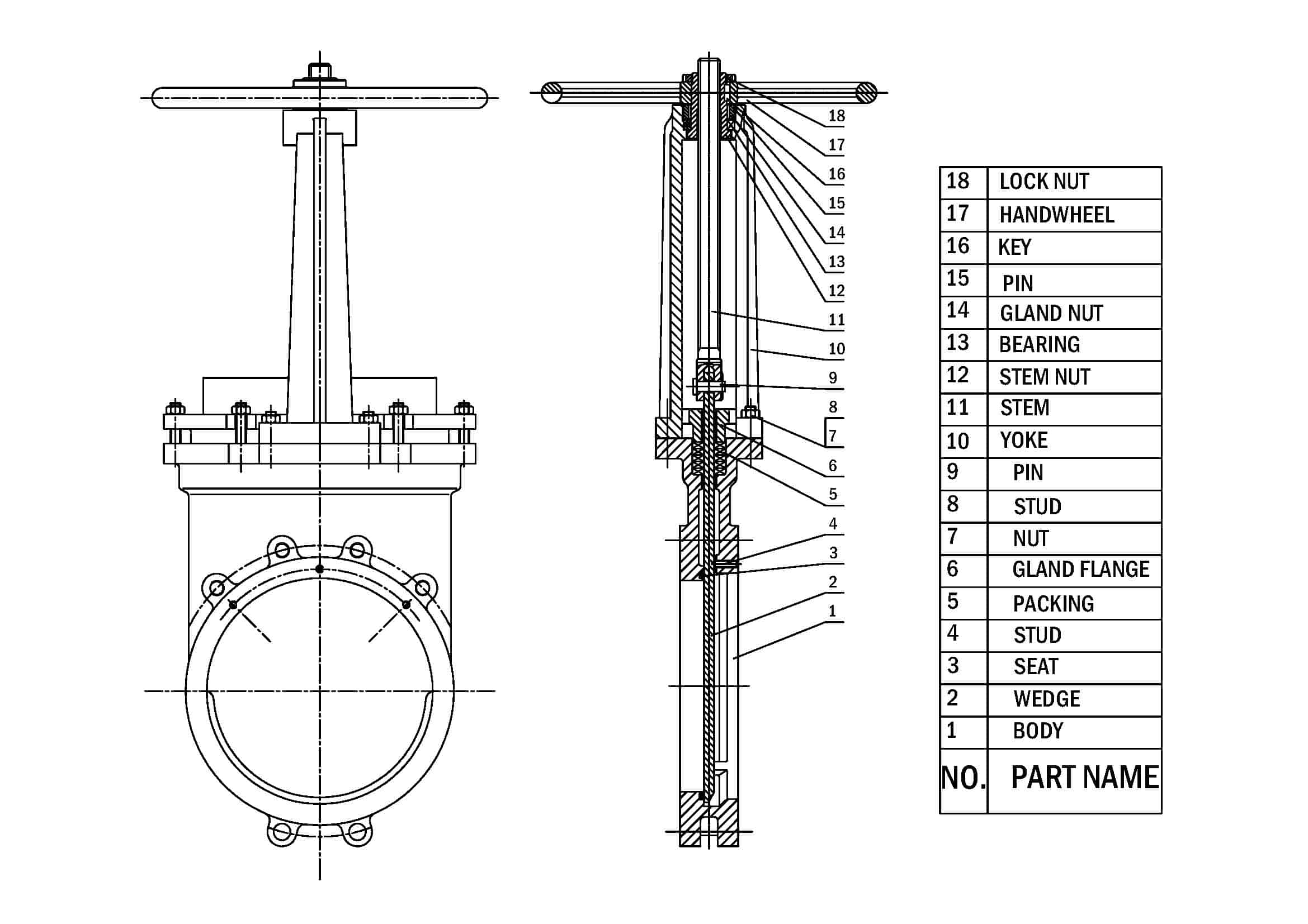

Diagram of Knife Gate Valve Parts List

Conventional resilient and metal seated knife gate valves are designed primarily for fluid isolation as they have poor control characteristics. Their ‘blade-like’ gate design makes them ideal for application where the process media is highly viscous or has a high percentage of solids. Their design offers a short face-to-face dimension which not only provides dimensional advantages but also allows for less internal area to be in contact with highly abrasive process media.

Typically knife gate valves are designed as isolation valves. However, there are specially designed knife gate valves that are used for process flow control. As it is with other types of valves such as ball valves, the main design feature that allows a standard knife gate valve to be suitable for control is the valve trim or design of the internal parts – primarily the closing membrane and seats. In the case of the control knife gate valves, the valve trim is designed to protect the exposed part to the highly abrasive process media normally using hard coatings and at the same time provide a design that will centralize the process media and allows for a more linear flow characteristic.

They are used in a wide range of industries such as water/wastewater, mining, pulp and paper, chemical and others.

[wptb id=25125]

Knife Gate Valve actuators

Knife Gate Valves, like any other type of valve, need a source of energy, such as pneumatic or hydraulic pressure, to be operated. Knife Gate Valve actuators can be selected depending on the source of power available to the actuator:

When pneumatic pressure is available, Knife Gate valve actuators can be:

Double acting linear pneumatic actuators, Cowan Series A

Single acting linear pneumatic actuators, Cowan Series AS

Single and double acting linear pneumatic actuators for control, Cowan Series AT

When hydraulic pressure is available, Knife Gate valve actuators can be:

Double acting linear hydraulic actuators, Cowan Series ML

Single acting linear hydraulic actuators, Cowan Series MS

When electric power is available:

Double and single acting linear electrohydraulic for isolation and controls, Cowan Series E2H

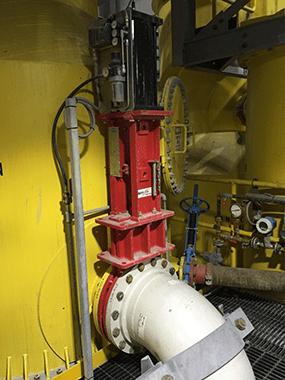

Knife gate valves with double-acting hydraulic actuators, Cowan series ML.

Control Knife Gate valve with double-acting pneumatic control actuator

Valve Standards

Various international standards for knife gate valves are:

- AWWA M72

- MSS SP 151 for Pressure Testing

- MSS SP 135 – High Pressure Knife Gate Valves

- AWWA C520 – Knife Gate Valves, Sizes 2 In. (50 mm) Through 96 In. (2,400 mm)

- MSS SP 154 – Low Pressure Knife Gate Valves for Double Block and Bleed

- MSS SP 146 – High Pressure Knife Gate Valves: Iron and Ductile Iron, Lug-, Wafer-, and Flange-Type

- ASME B16.10 – Face-to-Face and End-to-End Dimensions of Valves