Rotary Valve Actuators

Cowan Dynamics offers a comprehensive range of rotary valve actuators for control valve automation tailored for industrial applications. Our products are engineered for durability, reliability, and precise control, ensuring optimal performance in various industrial processes.

Rotary Valve Actuator Lineup

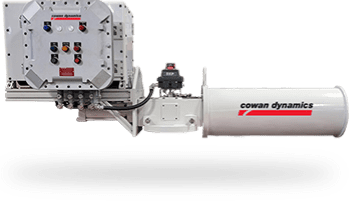

E2H-ESD

Electro-hydraulic ESD Actuator

The E2H-ESD is designed for Emergency Shutoff Valves and features a completely modular design consisting of the following modules: hydraulic power unit, hydraulic cylinder, scotch yoke mechanism, spring canister, and control panel for local and remote operation.

- Torque up to 3,000,000 in-lbs

- SIL-3 Capable (pending)

- Hydraulic Manual Override

- Operating Temp. -50ºC to 40ºC

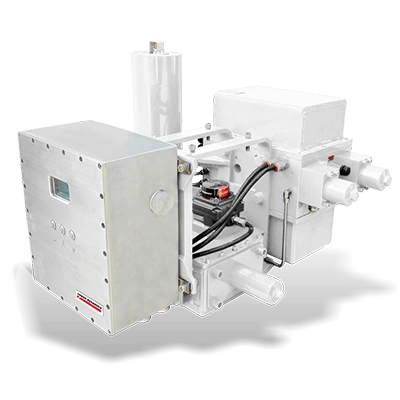

E2H90 Series

Electro-Hydraulic Valve Actuator

The E2H90 Electro-hydraulic Rotary Valve Actuator is used for industrial fields where highly reliable controlled valves are required. They are used to drive angular-stroke valves, linear-stroke valves, and lifting-lever-type ball valves.

- On/Off Service

- Operating Voltage: 220 VAC, and any global 3-Phase voltage ratings

- Fail-Last, Fail-Close or Fail-Open

- Operating Pressure 3000 psi

- Thrust up to 4,000, 000 in-lbs

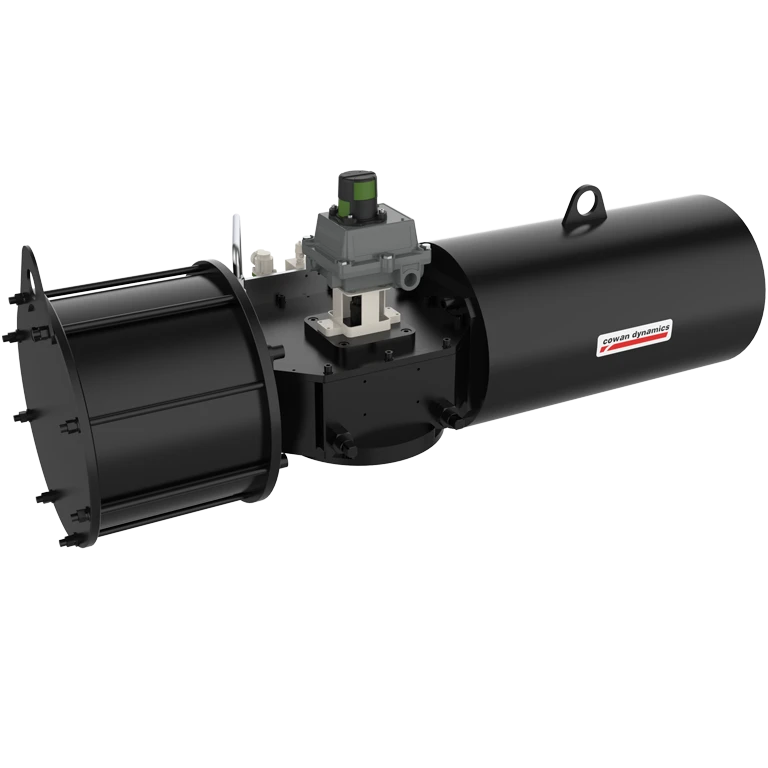

E2HR Series

Electro-Hydraulic Valve Actuator

The E2HR Electro-hydraulic Rotary Actuator features an all-in-one design and packs high performance into the smallest possible installation envelope for ¼ turn valve actuating applications.

- Torque up to 300,000 in-lb

- SIL-3 Capable (pending)

- Hydraulic Manual Override

- Speed 20°/Sec

- Torque up to 300, 000 in-lbs

- Standard Temp. -50ºC to 40ºC

CSY Series

Pneumatic Rotary Actuator

The CSY Pneumatic Rotary Actuator modular design that allows customization to fit specific needs. Bi-directional travel stop allows an adjustable stroke range of 80 degrees to 100 degrees. NAMUR mounting allows standardization of mounting hardware for a wide range of shaft-driven accessories.

- Double-Acting or Spring-Return

- Torques up to 2,500,000 in-lbs

- Operating Pressure: 40 – 100 PSIG

- Low Temp. -40ºC to 80ºC

- Standard Temp. -20ºC to 80ºC

- High Temp. -20ºC to 120ºC

CGO Series

Gas/Oil Rotary Actuator

The CGO Gas/Oil Rotary Actuator is suitable for Rotary (Quarter-Turn) valves with a linear design also available. Nitrogen Gas Application: High-sulfur natural gas and oil pipelines can use nitrogen gas as a power supply. Optional solar power module.

- Torques up to 4,000,000 in-lbs

- Air Supply Pressure: 5 – 150 Bar

- Electronic Line Break Protection

- Standard Temp. -15ºC to 80ºC

CRP Series

Rack & Pinion Actuator

Full compliance to worldwide standards and specifications. The CRP Rack & Pinion Actuator comes with an innovative universal drive shaft: Customized drive connections can be made in lieu of the standard double square bottom drive shaft connection.

- All moving parts are contained in Nylon bearings

- Torques up to 110,000 in-lbs

- Available in Double-Acting or Spring-Return

- PSI 115 psi

- Low Temp. -40ºC to 80ºC

- Standard Temp. -15ºC to 80ºC

- High Temp. -15ºC to 150ºC

Rotary Valve Actuator Applications

Oil and Gas

Empowering oil and gas operations with advanced valve automation, ensuring efficient flow control for upstream and downstream applications.

Chemical Processing

Maximizing chemical processing efficiency with cutting-edge automation and precision control technologies.

Mining & Processing

Boosting mineral processing productivity with innovative automation and control systems, like our dart valve automation products.

Water Treatment

Streamlining water treatment processes with advanced valve automation, such as regulating flow rates for precise flow control.

Power Generation

Enhancing power generation reliability through state-of-the-art valve automation, ensuring seamless operation of turbine control valves for optimized energy output.

Manufacturing

Revolutionizing manufacturing efficiency with precise actuation automation by optimizing the operation of advanced operations from aviation testing systems to industrial milling process control.

Learning Center

What are Rotary Valve Actuators?

Rotary valve actuators are designed to convert linear motion into controlled rotational movement, enabling precise modulation and shut-off of various rotary valves in industrial systems. These actuators work with multiple valve types, including ball valves, butterfly valves, plug valves, and rotary mixing valves. Their ability to provide floating control and maintain high control performance makes them essential for demanding applications such as heating, cooling, and fluid flow regulation.

Industrial rotary valve actuators offer a robust design and a simple installation process. They include mechanical interfaces that connect seamlessly with an output shaft to ensure reliable operation.

In applications other than industrial automation such as oil & gas, these actuators are commonly integrated into air conditioning systems to regulate cooling water temperatures, ensuring exact heating and cooling performance.

Whether in industrial applications or heating, combining a rotary valve and an adequately selected rotary actuator ensures smooth and efficient system function.

Mechanical Interface and Position Control Considerations

A well-integrated mechanical interface is crucial for ensuring seamless motion transfer between the rotary valve actuator and the valve itself. Proper positioning of the actuator helps prevent mechanical strain and enhances the overall efficiency of the system. Rotary actuators are designed to optimize stroke length, output shaft alignment, and system compatibility.

When selecting a rotary valve actuator, considering the position feedback mechanism is essential. Actuators with position control capabilities provide floating control and ensure precise linear motion, delivering improved performance in air conditioning systems, industrial automation, and heating applications.

Sizing the Correct Rotary Valve Actuator

Selecting the correct rotary valve actuator is crucial for ensuring compatibility with system requirements and achieving optimal performance.

Proper sizing considerations:

- Valve type

- Torque output

- Stroke length

- Power supply

- Rotary actuators come in various sizes to handle different operational loads and mechanical interfaces.

Key factors in selection:

- Required rotation angle

- Force needed for efficient valve operation

Standard selection process includes reviewing:

- Actuator stroke capabilities

- Power requirements

- Overload protection for durability and efficiency

Industrial applications, such as:

- Air conditioning systems

- Process control setups

- Require actuators with floating control and high control performance

To learn more about selecting the right rotary valve actuator for your system, view the latest products and resources from Cowan Dynamics. With a range of standard and customized options, Cowan Dynamics provides reliable rotary actuators that deliver precise positioning, efficient power use, and long-term durability.

Ensuring System Efficiency with Proper Selection and Error Prevention

Selecting the right actuator requires considering system parameters such as size, stroke, and power supply compatibility. Ensuring the correct actuator size prevents unnecessary system overload, reduces errors, and delivers optimal performance in heating and cooling applications.

Common errors in actuator selection include undersized actuators that fail under load conditions and oversized actuators that consume excessive power. Proper assessment of size, mechanical interface requirements, and stroke alignment helps prevent such issues. Reviewing system requirements, page specifications, and actuator product catalogs can simplify the selection process.

For recent advancements in rotary actuator technology, view resources from Cowan Dynamics to learn more about standard and customized solutions tailored to industrial needs.

Maintenance of Rotary Valve Actuators

Proper maintenance of rotary actuators is essential to ensure reliable operation and extend product lifespan. Many modern actuators, such as Cowan’s lineup of rotary valve actuators, are designed to reduce downtime and operational errors.

Routine checks should focus on mechanical interfaces, power supply connections, and the actuator’s stroke limits to prevent system overload.

To maintain optimal performance, periodic inspections should account for correct valve positioning, torque requirements, and potential wear on critical components such as the piston and output shaft. Regular maintenance ensures that rotary valve actuators deliver precise control while maintaining floating control capabilities in applications such as industrial automation or air conditioning systems. A well-maintained valve actuator will enhance reliability and prevent breakdown, ensuring uninterrupted process efficiency.