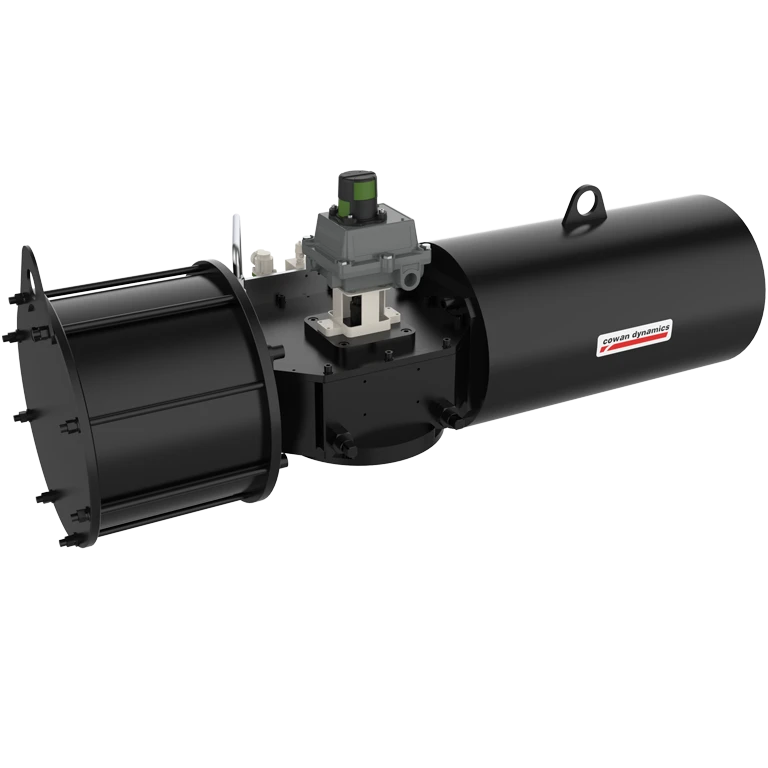

CSY SeriesScotch Yoke Actuator

Pnuematic rotary actuator for valve automation.

Specifications

Specification Overview

Torques up to | Double-Acting – 2,212,686 in-lb |

|---|---|

| Spring-Return – 635,067 in-lb | |

| Operating Pressure | Pneumatic – 40 – 100 PSIG |

| Material Breakdown | Standard |

|---|---|

| Head & Cap | Ductile Iron |

| Barrel | Carbon Steel |

| Piston | Ductile Iron |

| Tension Rod | Alloy Steel |

| Hydraulic Cylinder | Carbon Steel |

| Hydraulic Piston | Carbon Steel |

| Scotch-Yoke | Carbon Steel |

Design & Materials

Click on the (+) Icons to see more details.

NAMUR Mounting | Allows standardization of mounting hardware for a wide range of shaft-driven accessories.

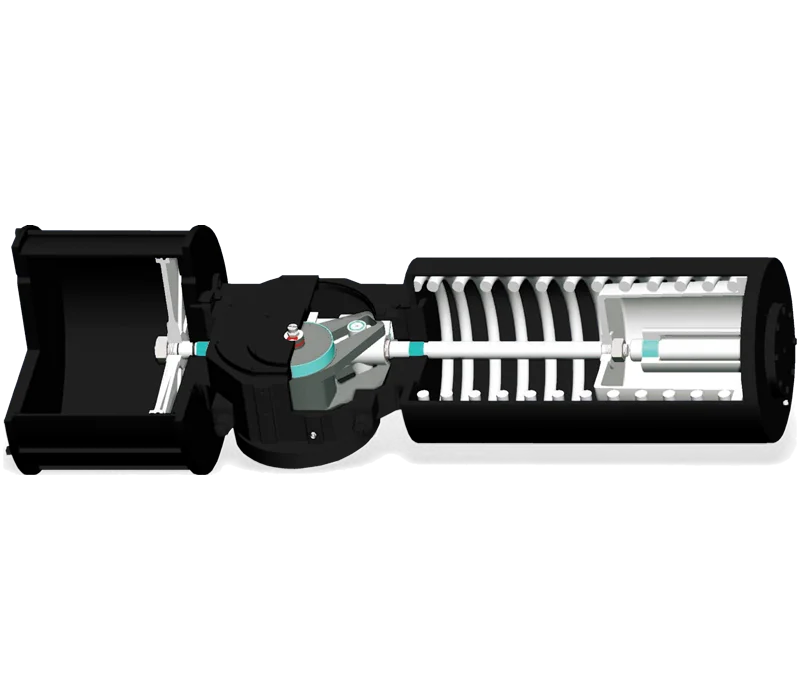

Replaceable Bearings | Protects sliding and rotating components, and are suitable for dry or lubricated working conditions.

PTFE Guide Ring | Prevents contact between the metal surfaces of the piston and pneumatic cylinder, prevents internal damage to the cylinder while providing self-lubrication and low friction.

Integral Housing Vent | Releases overpressure while preventing ingress of foreign objects or water.

Travel Adjustment | Bi-directional travel stop allows an adjustable stroke range of 80 degrees to 100 degrees.

Roller | Connects the Scotch yoke and yoke pin, reducing friction and wear between both components.

Safe Spring Lock

PTFE Guide Bar | Prevents yoke pin axial movement, transfers axial loads directly to the drive module case.

Spring Module with Hydraulic Override | Located inside the hydraulic override cylinder module on spring-return models so that the actuator length is not increased.

Scotch Yoke Actuator Applications

The CSY Series scotch yoke actuator can be used in many industrial applications.

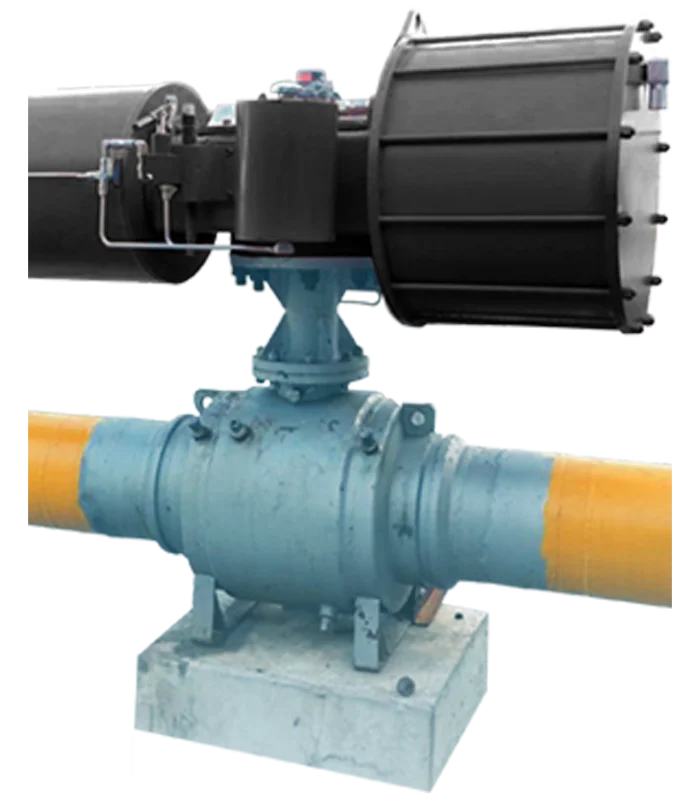

Oil and Gas

The CSY Series scotch yoke actuator ensures precise control over valve movements, facilitating efficient flow regulation in pipelines, while also enhancing safety and reliability in critical operations.

Chemical Processing

The versatility of the CSY Series scotch yoke actuator enables seamless adjustment of valves, ensuring optimal conditions for chemical reactions and material flow, thereby boosting process efficiency and product quality.

Mining

The CSY Series scotch yoke actuator plays a pivotal role in controlling valves and dampers, enhancing the safety and efficiency of material handling processes, while also minimizing downtime and maintenance costs.

Power Generation

The robust performance of the CSY Series scotch yoke actuator enables accurate regulation of valves in steam turbines and other power plant equipment, contributing to enhanced operational efficiency and reliability.

Water Treatment

Water treatment facilities rely on the CSY Series scotch yoke actuators to precisely manage valve operations, ensuring effective filtration, disinfection, and distribution processes, thereby maintaining water quality and safety standards.

Manufacturing

In manufacturing environments, the CSY Series scotch yoke actuators automate machinery operations with precision, enhancing production efficiency and consistency while reducing manual labor and operational errors.

Datasheets & Videos

Mounting Kits: ISO, MSS & Customized Patterns Available

Cowan valve mounting kits for our Scotch Yoke Actuator can be designed for any rotary valve. Mounting kits available in steel and stainless steel construction.

Automation Packages

Integration of Control Accessories – Solenoid Valves; Pilot Valves; Quick Exhausts; Positioners

Limit switches and position sensors; Field-Adjustable for open and close indication; Analog and digital feedback

Automation Packages

C-PAC Module: Cowan Pneumatic Actuator Control – Compact, Versatile, Simple, Cost Effective; Designed for Linear and 1/4 Turn Actuators; Fail Close, Open, Last or Lock; Cv up to 11.1